704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

Category

Shapers

77 Results Found

704-841-2001

$33,900

CAM-WOOD RD-5412-SC Tenoner with Dowel DrillTenoning/Coping machine for straight or miter material. Great machine for miter door production or stile and rail stock. Equipped with: -- 6" High stackable spindle by pneumatic up & down with (3) different stops; easily and accurately setup for each cutter position. -- Drill heads for dowel hole at each end. -- One shaper head at each side of the table. -- Table moves from right to left by variable speed Pneumatic-Hydraulic power to achieve the fully cutting power. -- Twin table moves in and out separated for tongue and groove, end match application. -- Twin heavy-duty pneumatic pistons hold down the workpieces tightly to the table during the cutting process.Features: -- Rigid construction on the heavy sheet metal frame, cast iron table & base for durability usage. -- Heavy-duty industrial motor is suitable for heavy duty cutting under full load. -- Linear guide rails and bearings let the operator moving the table smoothly. -- Cast iron fence locks in the table groove to finish 45° cut easily. -- Automatic cycle function, just place the material against the stops, the machine will automatically clamp, move in for shaping/tenoning, come out and release the hold down.

$5,190

CAM-WOOD SP-35G Fixed Spindle ShaperA Shaper with plenty of cast iron... a solid piece of machinery!Features & Specifications: -- .Precision ground cast iron table and T-slot miter gauge slot. -- Perfect alignment, rigid spindle supported by a power transfer system for accuracy. -- Individual micro adjustment fence on both sides of the spindle by hand wheels. -- Large hand wheel for fast movement and lock protection. -- Magnetic switch for overload protection. -- Spindle travel is operated by a rack and scroll gear. -- Two spindle speeds for versatile cutting. -- Forward and reverse switch for cutting directions. -- Heavy gauge metal cabinet base. -- Alloy steel spindle for durability usage. -- Sealed long-life ball bearings. -- Standard equipment: Full power motor, dust chute, table insert, spring hold-downs, miter gauge. -- Table Dimensions: 30" x 40". -- 1-1/4" Standard Spindle Dia. --Spindle Speed: 4,000 - 10,000 RPM. -- 5 HP Motor. -- 4" Dust Hood.

$2,490

CAM-WOOD SP-30 Fixed Spindle ShaperA Shaper with plenty of cast iron... a solid piece of machinery!Features & Specifications: -- 5 HP Motor with reversing switch. -- Interchangeable spindle as standard with a 1" & 3/4" spindles. -- Spindle with 4" under nut. -- (2) Spindle speeds of 8,000 & 10,000 RPM. -- Large 30" x 28" cast iron precision ground table. -- 7" Max. table ring. -- Easily locked spindle for cutter change. -- Micro-adjustable back fence with material spring holddowns. -- Includes Miter gauge, cutterhead guard assembly, and operators manual.NOTE: Available in 3-Phase and 1-Phase electric.SP-305C 2-PCS ROUTER BIT COLLECTOR SET $ 89.00.

$8,180

CAM-WOOD SP-750x Heavy Duty Shaper. 7.5 HPSpecifications: -- Table size: 48 x 36.5'' -- Height of Working Table: 35-1.2". -- Spindle 1'',1.25''. -- Motor: 7.5 HP (10 HP Opt.). -- Speed (RPM): 3,000/4,500/7,500/10,000. -- Dimensions: 53' 'x 43'' x 51''. Weight: 1480 LbsFeatures: --Designed for heavy industrial work. -- Industrial powerful motor for maximum cutting capacity. -- Quick-change spindles. -- Forward / reverse switch. -- Individual two-sided micro adjustable fence. -- Precision ground large cast iron table. -- Three spindle speeds for versatile cutting. -- Sealed long-life ball bearing. -- Metal 4"; dust hood. Heavy sheet metal cabinet base for durability usage. -- Magnetic control for overload protection.

$11,200

CANTEK - SS512TB Tilting Spindle ShaperSpecifications: --Tilting spindle from -5° to +45° and 6" x 43" fence. --1-1/4" interchangeable spindle is standard (other sizes available). -- Large cast-iron table is ground and polished for maximum stability and durability. -- Powerful 7.5 HP motor for even the most demanding profiling work. -- Five spindle speeds can be easily adjusted to suit your tool diameter. -- 5-1/2" Useable spindle length, above table 13-¼"; below table 8-¼". -- Electronic spindle brake for added safety and facilitates fast changeover. -- Precision fence assembly with micro-infeed and outfeed fence adjustment. -- The finger-style fence allows the fence to be adjusted around the cutter for added safety and workpiece stability. -- Table size 31 ½"; x 39.4″. -- Dust port (1) 5″ on guard, (1) 4" into the table.

$10,500

CANTEK SS512CSB Heavy Duty Production Shaper with Sliding Table & Spindle Brake7.5 HP Features: -- Cast iron sliding table runs on ball bearing for smooth table transition. -- Cast iron ground & polished table with insert rings; table size: 31- ½"; x 39.4″. -- Precision ground and electronically balanced spindle. -- V-belt drive with (5) feed speeds is easily accessed from the front of the machine. -- Electric spindle brake for added safety. -- Spindle lock - with limit switch safety, machine will not start with lock engage. -- Micro spindle height adjustment with dial indicator. -- Interchangeable cutter spindle. -- Forward/reverse spindle rotation. -- Adjustable "finger" type fence Independent micro-fence adjustment on both sides. -- Includes the following standard equipment: 1- 1/4" Spindle, (1) 5"; dust chute on guard & (1) 4"; dust chute in the table, safety guard, Miter tenon jig, and Telemecanique magnetic controls.Net weight 1034 Lbs. Machine dimensions 48.4"; x 39.4"; x 52 ¾";. Shipping weight 1166 Lbs.Shipping dimensions 45 ¼"; x 37"; x 41";

$13,300

CANTEK SS-512TSB Tilting Spindle and Sliding Table Shaper:7.5 HP - 3-Phase motor, overall table dimensions 31.50" x 39.40", sliding table 10.25" x 39.40". -- Spindle stroke 7"; 1-1/4" dia. spindle with 5 MT receiver and 4-3/4" cap. under the nut. Spindle tilts -5° & +45°. -- (5) Spindle speeds: 3,000, 4,000, 6,000, 8,000 & 10,000 RPM.Complete with: Spindle reversing switch, micro-adjustable fence 6" x 43", thermal overload protection and dust hood.16 weeks delivery.

Call for Price

--In Auction: https://exfactoryauctions.com/Detail/SA-231009/event/A122024$1 --No RESERVE!-- CHIA LUNG KR-30 2-Spindle Dual Table Automatic Rotary Copy Shaper Equipped with: (2) 19” Dia. x 35-1/2” H Tables. (2) 6-1/4” Dia. Center clamp plates.

$7,680

COMEC - FAS/2, ...Corner Milling MachineCOMEC FAS is a dedicated milling machine with: Inclinable heads for machining the corner of chair seats. Specifications: -- (2) Heads with: 5.5 HP motor and 40 mm spindle shaft. -- Max. cutter size: 150 mm (5.9"). -- Tilting of milling units: 20°/ +45° in horizontal plane. -- Fixed left hand column to support head unit. -- Max. working height: 200 mm (7.8").

$4,250

DELTA RS-15 SINGLE SPINDLE SHAPERSpecifications: -- 1-1/4" interchangeable spindle. -- 7.5 HP motor with (5) spindle speeds of 2,800 - 4,500 - 6,000 - 8,000 & 10,000 RPM. -- Vertical spindle travel is 7-3/4", with 5-5/16" capacity under the nut. -- 35-1/2" x 43" fixed table with 13" max. table insert diameter.Complete with: -- Spindle reversing switch, spindle foot brake & lock, and adjustable fence. -- HOLZ Power Feeder is included

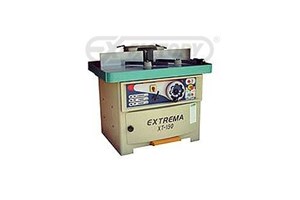

$2,539

EXTREMA ET-100 Fixed Spindle Shaper; "Extremely" well-built and with solid features. -- Single phase with 3 HP or 3-phase with 5 HP motor. -- Interchangeable spindles of 1-1/4" and 3/4". -- (2) Spindle speeds of 7,500 & 10,000 RPM. -- Heavy cast iron table with a 6" max. table ring. -- Spindle lock, micro-adjustable back fence and reversing switch. -- Miter gauge, 1/2" router collet adapter and cutterhead guard.

$3,025

EXTREMA ET-120 Spindle Shaper;"Extremely" Well-built and with solid features. -- 5 HP Single-phase motor. -- Interchangeable spindles of 1-1/4" & 3/4" and (1) router collet adapter. -- Dual drive belts and (2) spindle speeds of 7,500 & 10,000 RPM. -- Heavy cast iron table with a 6" max. table ring. -- Spindle lock, micro-adjustable back fence and reversing switch. -- Complete with: Miter gauge, 1/2" router collet adapter and cutterhead guard.

$2,528

EXTREMA ET-120.3 Shaper w/Fixed Spindle; "Extremely" Well-built and with solid features. -- 5 HP motor. -- Interchangeable spindles of 1-1/4" & 3/4" and (1) router collet adapter. -- Dual belts and (2) spindle speeds of 7,500 & 10,000 RPM. -- Heavy cast iron table with a 6" max. table ring. -- Spindle lock, micro-adjustable back fence and reversing switch. -- Miter gauge, 1/2" router collet adapter and cutterhead guard.

$6,600

"Extremely" Well-built and with solid features. -- Solid spindle of 1-1/4" with 5-13/16" under nut. -- Dual belts and (3) spindle speeds of 5,500 - 7,500 & 10,000 RPM. -- Heavy cast iron table with a 12-3/8" max. table ring. -- Spindle lock, micro-adjustable back fence and reversing switch. -- Large 7.5 HP motor. -- Miter gauge, cutterhead guard assembly, operators manual, and tool kit.

$7,200

EXTREMA ET-160 Fixed Spindle Shaper;"Extremely" Well-built and with solid features.Specifications: -- Solid spindle of 1-1/4" with 5-13/16" under the nut. -- Large 10 HP motor. -- (3) Spindle speeds of 5,500 - 7,500 & 10,000 RPM. -- Heavy cast iron table with a 12-3/8" max. table ring. -- Spindle lock, micro-adjustable back fence, and reversing switch. -- Miter gauge, cutterhead guard assembly, operator's manual, and tool kit.

FLETCHER EZ-DOOR Raised Panel Door MachineThis freestanding machine can produce an entire 5-piece door in a matter of minutes. Easy to operate, the E-Z Door has a 4-position configuration to produce raised panels, cope/stile profiles and mullions for glass doors. Cathedral doors are produced by using a quick change template system.Specifications: -- Select cutter and material stop with the press of one button. -- Simple four position one spindle design. -- PLC controlled pneumatics. -- Rigid lubricated spindle assembly. -- Re-circulating ball bearing slides. -- 10 HP 230 or 460V/60HZ spindle motor – (460V/3PH=17FLA) – (230V/3PH=33FLA) -- 6,500 RPM spindle speed. -- 62 inch travel length standard with circulating ball bearing slides, cut rails to 59"; and panels to 55"; -- Includes: (4) Standard cutters (shape to be decided), others optional. -- Includes: one template of customers choice. -- 1-¼"; Arbor. -- CFM requirement is 392.Made in North Carolina, USA!

$3,950

Gomad "DFDA-455" Sliding Table Single Spindle Shaper -- Specifications: 2 -1/64" (55 mm) spindle currently, 7.5 HP belt drive motor, (4) speeds 4,000/6,000/8,000 & 10,000 RPM, 3-9/16" spindle travel, 3/4" up to 2-11/64" dia. interchangeable spindle, reversing spindle rotation; heavy duty 36" x 40" cast iron table, (3) pneumatic clamps, double end fence, 4.5" dia. dust chute. -- Complete with: 13" wide sliding table, (4) Hold down springs, mounting collars & bolts, miter gauge with stop rod, and foot brake, capable of doing arch moulding work.NOTE: Great running condition before disconnect in 2013, currently stored in facility basement.

Call for Price

//This machine is in an Auction on exfactoryauctions.com// //Link to machine: http://exf.ac/i62 GRIZZLY G7214Z Shaper Specifications: 1-1/4" Dia. interchangeable spindle, 7.5 HP - 3,450 RPM motor; 3,600, 5,100, 8,000 & 10,000 RPM spindle speeds via 4-step V-pulley. 5-1/8" Cap. under nut when using the 1-1/4" spindle, 3-1/4" spindle travel, 34-3/4" x 35-1/2" cast iron table, 43" working height. Table Counterbore: 7" dia. x 5/8" deep Complete with: Adjustable Fence with integrated 4" dust collection shroud, reversing switch & magnetic controls, 3-roll power feeder

$1,350

GRIZZLY - G1026, ...Single Speed Shaper w/Feeder & Mobile Base3 HP - 3,450 RPM Motor; 1/2", 3/4" & 1" dia. interchangeable spindles; 2-1/2" spindle cap. under the nut and with 3" spindle travel. -- (2) Spindle speeds of 7,000 or 10,000 RPM; reversing spindle switch. -- Features: 28-1/4" x 21-3/4" table; 34" table height.Complete with: Magnetic spindle brake, adjustable fence & 3" dia. dust extraction outlet.3-Roll 4-Speed Power Feeder & Mobile Base!

3/4 HP Single Shaper with Team B&B Tiltrod Shaping Gig!Precision-ground cast iron table, independently adjustable fence halves, Push button ON/OFF switch.Includes: Miter gauge and starting pins, Cast iron body construction, Pre-formed steel stand, shielded & permanently lubricated spindle bearings, Reversing switch Includes Team B&B Tiltrod Shaping Gig. Features: -- Motor size: 3/4 HP -- Motor Speed: 3450 RPM -- Table size: 15-5/8" x 17-3/4", Working Height: 34-1/4" -- Vertical Spindle travel: 7/8" Spindle speed: 8500 RPM