704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Sawmill

660 Results Found

704-841-2001

DENRAY 9600 B Down Draft Sanding TableExtra large 48" x 96" table; Comfortable 36" working height. -- Powerful system with 4,800 CFM rating. -- 5 HP Motor with magnetic starter. -- Space-saving self-contained unit w/built-in dust drawers and high efficiency cartridge filters. -- No duct work, no loss of conditioned air. -- 1-1/8" Thick hardwood frame worktable with 3/4" thick MDF board and rubberized surface. -- Fully enclosed unit. -- "Self-Cleaning" System with push button start to force compressed air from a storage tank into the filters and force dust into the dust drawer. -- Floor level air exhaust that can be directed away from operator. -- Quiet operation with only 82 dB. -- Available options; (4) Swivel casters with (2) that lock in place, Auto-Self cleaning timer or muffler.

DENRAY 7200 B DOWN DRAFT TABLELarge 48" x 72" Table. -- 3,900 CFM rating after filters. -- 5 HP Motor w/magnetic starter. -- Space-saving fully self-contained unit: No duct work, no loss of conditioned air. Contains (2) cartridge filters that clean to 0.5 microns. -- Comfortable working height 36". -- 1-1/8" Thick hardwood frame worktable with 3/4" thick MDF board and rubberized surface. -- "Self-Cleaning" System with push button start to force compressed air from a storage tank into the filters and force dust into the dust drawer. -- Floor level air exhaust which can be directed away from the operator. -- 84 dBA Sound level. -- Options include; Timer to automatically clean filters without operator, (4) swivel casters (2) that lock into place, noise reducing muffler (Reduces volume by 10 to 12 dBA),Unit also available in 220 V single-phase.

Call for Price

DAC-1200 - DENSACAN: Can DensifierThe "DAC-1200" is fully automatic and will run continuously as long as cans are fed.Features -- Automatic shut off when empty. -- Capacity in pounds/hour. ● Aluminum: 1,200 Lbs. ● Aluminum: Flat 2,000 Lbs; Ferrous: 2,500 Lbs. -- Biscuit description; typical size: 11" x 13" x 9". -- Motor: 20 HP.

DEVAIR 447 15 HP 2-Stage Horizontal Tank-Mounted Air CompressorSpecifications: -- Cap. 51.8 CFM, Max. pressure 175 PSI.Complete with: -- 120 Gallon Cap. 24"; Dia. x 60"; L Horizontal Air Receiving Tank.

$2,000

DEVAIR 447 15 HP 2-Stage Horizontal Tank-Mounted Air Compressor Specifications: Cap. 51.8 CFM, Max. pressure 175 PSI. Complete with: 120 Gallon Cap. 24” Dia. x 60” L Horizontal Air Receiving Tank. CURRENCY NOTE: Negotiable Price is listed in U.S. Dollars.

$6,350

DEWALT GA 16" Radial Arm Saw Specifications: -- 5 HP TEFC Saw motor; 16" dia. blade; 1" x 3-1/8" saw arbor; 4" thickness cap. @ 90°, 19" crosscut cap., cutting 1" board with long arm. -- Complete with: -- Blade guard, magnetic starter, stand, carriage return mechanism. -- Optional: -- Electric brake. -- Photo not of actual machine.

$10,900

DEWALT - 35 Series Super Duty, ...22" Radial Arm SawSpecifications: -- 7.5 HP TEFC Saw motor; 22" dia. blade; 52" long arm; 1" x 3-1/8" saw arbor; 7" thickness cap. @ 90°; 26" crosscut cap.; 40" rip cap. -- Complete with: -- Blade guard, magnetic starter, stand, and carriage return mechanism. -- Optional: Electric brake.

DEWALT 10" Radial Arm Saw. -- Specifications: -- Blade diameter: 10"; Table size: 27" x 30" x 36" H.

$9,300

DEWALT GE 20" Radial Arm Saw Specifications: -- 7.5 HP TEFC Saw motor; 20" dia. blade; 1" x 3-1/8" saw arbor; -- 6" Thickness cap. @ 90°, 27" max. crosscut cap. cutting 2" board; 42" rip cap. with 52" long arm; 2" dado capacity. Complete with: -- Blade guard, magnetic starter, stand, carriage return mechanism. Includes: -- (1) New 20" blade.Optional: -- VFD Electric brake.Note: Photos are not of actual machines, but they represent the state of "Reconditioning"

$6,850

DIEHL - DMG -12, ...Profile GrinderSpecifications: -- 1/2" Width cap. and 10-1/2" max. cutting circle. -- 1 HP TEFC Motor with 2,260 RPM grinding spindle. -- (2) 1-13/16" Dia.; 16" X-axis & 6" Y-axis table movement. -- 30° Clockwise & 90° counterclockwise base swivel rotation for face grinding of profile cutters or planer knives. -- +30° to -30° Vertical grinding spindle adjustment. -- 2" In & out adjustment. -- 1" X-Axis & 1-7/8" Y-axis template adjustment. -- 7" Min. & 10" max. grinding wheel dia.Equipped with & Features: --Coolant pump with 5-gallon tank.

Call for Price

Call for Price

DISA NFK 9 - 2BL Modular Dust Collector. Up to 45,000 CFM @ 6.25 to 1 air-to-cloth ratio, and @ 11.6" w.g. external static pressure; modular, expandable Heavy Duty Baghouse. -- 7,200 Sq/ft of filter area, mad up of (450) filter bags. -- Filter consists of (9) Filter module sections with access door in each section and (2) blank inlet module sections with (9) 2 HP regeneration fans for cleaning of filter media and (2) blank entry modules. -- Comes with: (1) 60 HP Belt drive COMBIFAB blower package w/drive guards; motor & fan are a common steel base/frame with ground level installation. Fan delivers about 20,000 CFM. There is sufficient filter capacity for at least 75 - 100 HP second fan/motor. -- Complete with: Outside separate elec disconnects for each cleaning fan. -- "NRS-10" Rotary air lock for bottom discharge with 2 HP TEFC motor; Steel support members dismantled.. -- Includes: Some outside pipe (and main headers explosion/access doors -- Note: (2) cleaning fans are missing and will be supplied at cost. -- Actual model is NFK2000 9+2 BL HJLR.

Call for Price

DISA CS-4 MAXI Dust collector with Rotary Air Lock. Approx. 16,000 CFM at 8.7:1 air-to-cloth ratio; 1,725 sq. ft. of filter area, with (128) filter bags filtering to 3-micron. -- General Info: CS-4-M consists of (3) filter modules & one entrance module. -- Comes with: DISA, S56-500 Material Handling fan powered by 50 HP TEFC motor. Fan nominal rating: 16,000 CFM @ 9" SP. Fan is currently mounted on elevated support but can be installed on the ground as well. -- (3) Reverse air bag cleaning modules with motorized fans that clean the bags every (4) hours of operation automatically, each with 2 HP fan motor. A damper at inlet closes during cleaning cycle to prevent blowback. -- Complete with: Hopper bottom as collected dust is conveyed to one end where a NRS-20 Rotary Air Lock where dust is discharged into Transfer fan. Filtered air return unit, 8' support structure to allow for dumpster under Dust Collector. -- Includes: Control panel, motor starters and switches, and Explosion Panels. Material handling main fan w/motor mounted to side of base module. -- 26" diameter inlet pipe, 97" clearance under collector for dump hopper, free standing steel bolt-together structure, -- Features: Dust transfer from bottom of Rotary Air Lock to enclosed container by separate floor mounted material handling fan, approx 7.5 HP. -- Note: Pictured storage bins are not included.

DONALDSON / TORIT DWST6-5 Cartridge Dust CollectorDownflo® WorkStations (DWST) fit anywhere on the plant floor and apply NO restrictions to worker movements or visibility. The full line of WorkStations are designed specifically for those in-plant areas where dirty and/or noisy operations are out in the open—grinding, sanding, chipping, batch mixing or welding. The DWST delivers exceptional performance in metalworking, woodworking, and process applications where high filtration efficiency and ledge less construction is often a requirement. Specifications: -- (5) Module System, each with 10 HP motor, 7,000 CFM. -- (4) Ultra-Web cartridges. -- Pulse-cleaning manifolds and ventures, (2) dust drawers. -- (1) Acoustical panel per module. Louvers mounted on lower section of unit.Includes: -- (1) IEC control panel includes 460-volt motor starters, circuit protection for each motor, transformer, programmable logic controller. -- Magnehelic gauge mounted in a panel door, start/stop buttons, and a through-the-door disconnect switch. -- Pulse cleaning can be continuous or after-shift. -- All components are IEC rated. The enclosure is rated Type 12. -- 1"; Compressed Air Regulator with Filter Separator and Gauge, Black Iron Fittings, and Black Iron Piping Required for Cleaning System. -- Provides a 1"; Common Connection Point for Design Shutters to Tie into with Existing Compressed Air System.

DONALDSON / TORIT - 2DF-16, ...Cartridge Dust CollectorSpecifications: -- Holds (16) cartridge filters. -- Includes "New" AirMax Premium Media Cartridge Filters: Fire retardant. -- Total filter media area: 3,616 ft². -- Air-to-Media ratio @ 8,000 CFM is 2.2:1. -- Automatic Pulse Clean System with: Differential pressure gauge and sequencing control in enclosure. -- (2) Hopper outlets with sealing drum cover kits. -- Steel support structure. -- Includes: 20 HP Top mount, direct-drive Blower. -- Rated for 8,000 CFM. -- Electrical motor starter & controls. -- Includes: Installation/Operation/Maintenance Manuals.Sold with 6-Month Mechanical Warranty

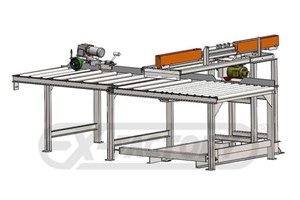

DOUCET BT3-30-5-23-G-PT Return Conveyor for EdgebandersSpecifications: -- Right-hand feed, with Left-hand return. -- Min. part size 4" x 12". -- Max. panel size (with operator assistance supporting then turning panels) 45" x 96".Equipped with: -- 1-1/2’ L Infeed roller conveyor section, with (5) 23-1/4"; W & (2) 34-1/4"; W Rollers. -- 34-1/4"; W x 5-1/2’ L x 35"; H Receiving table, with Automatic/Manual height adjustment 2". -- (8) 3/8"; Dia. transfer belts, (3) on 3"; Centers, (2) on 6"; Centers, & (3) on 9"; Centers. -- 29-1/2"; W x 5-1/2’ L x 34"; H Return table. -- 29-1/2"; W x 18’ L x 34"; H 3-Section Return conveyor, with 5-1/2"; W x 6’ L Gravity roller conveyor side extension. -- All rollers 1-7/8"; Dia. covered line shaft on 3"; centers.

$132,700

LHI RFPR ROLL FEED PANEL RIPPER - "BUILT TO ORDER SYSTEM" with the following equipment: -- Ripsaw: -- 72" Arbor - 50 HP arbore motor and 14 to 80 FPM Variable Speed Feed Rate (4-speed programmable via VFD) -- (8) Polyurethane Feed Rollers -- Arranged for 10" dia. blades to rip panel thickness from 1/8" to 1-1/2"; -- Single Point Thickness Adjustment -- Quick-Change Arbor Kit Additional Arbor Setup Including: -- (1) Arbor Cart, (1) Blade Box, (1) Arbor Shaft, (1 set) Bearings, (1) Arbor Sheave, and (1) Throat Plate Rack Automatic Infeed System: -- 4,500 Lbs. Capacity Hydraulic Scissors Lift with (4) loading ramps to feed and align 4’ x 8’ sheets into Panel Saw -- 110VAC/1PH Scissors Lift power unit -- Auto-Cycling Rake Feeder -- 6’ Line-Up Conveyor With Power Pinch WheelOutfeed Scissors Lift: -- 4,500 Lb. Capacity Hydraulic Scissors Lift with 4' x 8' top, (3) support ramps/cross-bars to allow fork access -- 110VAC / 1Phase power unit -- Auto Down Indexing -- Auxiliary Foot Pedal Control Blades, Collars and Throat Plates: 10" x 40T x 4 3/16 Bore, TGC, $105 eachBlade Collars: 3-15/16" ID x 4.18" bore x 1.25" wide, $135 eachAluminum Throat Plates, $35 each TERMS AND CONDITIONS: -- Delivery: 16-18 Week ESTIMATED delivery date assumes your order is received within one week of date of this quotation. -- A 5% Tooling & Steel Surcharge to be added to the machinery price when the total is known -- Installation technical assistance, $125/hr. plus travel time and expenses (if required) -- Customer responsible for own rigging -- Quote assumes customer will deliver material for testing (if required) -- Warranty: 1-year mechanical parts (electrical controls excluded) -- FOB: Shannon, MS 38868. ESTIMATED SHIPPING DATE: 16 TO 18-WEEKS --The delivery date is quoted as “estimated"; because the equipment manufactured is built to our customer's specifications. This estimate is made under the assumption that there will be no interruptions of labor, material shortages, or any environmental or other unforeseen circumstances. -- LHI is not responsible for any installation or production costs resulting from actual delivery dates which exceed the quoted estimated delivery dates. Accurate dates for the delivery will not be available until the equipment is in the manufacturing phase. If there are custom features for the quoted equipment then accurate delivery dates will be available when testing is complete. Please consult with the factory for updates to the expected delivery date.NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE

$52,733

LHI PIGTAIL Crosscut saw with conveyor and air stopSpecifications -- 62" Cut width --Saw motor 5 HP -- 14 FT gravity conveyor cutting surface -- Cam Lock adjustable stop -- Power feed wheel for rip saw infeed assist -- Blade dia. 12"Equipped with and Features -- 4,500 lb lift with loading ramps 1 HP, 30" X 72" platform -- 4,500 lb Outfeed lift with 3 ramps, 48" X 96" Platform, Auto down indexing -- 10" X 40T X 4-3/16" , 30 Blades -- 3-15/16" ID x 4.18" bore x 1.25" wide 30 collars -- 32 Throat Plates

$84,714

LHI MODEL RFPR ROLL FEED PANEL RIP SAW WITH THE FOLLOWING STANDARD AND SPECIAL EQUIPMENT: Specifications: -- 72" Useable Arbor and 50 HP Arbor Motor -- 14 - 80 FPM Variable Speed Feed Rate (4-speed programmable or potentiometer) -- (8) Polyurethane feed rollers -- Arranged for 14" dia. blades and 4"; max cutting thickness -- Single Point Thickness Adjustment from 1/2" to 4" -- Arbor Quick-Change KitComplete with: -- Additional Arbor Setup, Includes: Cart, Blade Box, Arbor, Bearings, Sheave, Throat Plate Rack, and (6) Throat Plates -- (15) Blade Collars: 3-15/16" ID x 4.18" bore x 1.25" wide -- (15) 14" Carbide Tipped Blades: 40 Tooth with 4.188 bore -- Delivery ESTIMATED at (14) weeks; assumes order and down payment are received within (30) days of the date of this quotation. -- Technical Installation assistance - $125/Hr plus travel time and expenses -- Buyer is responsible for rigging -- Quote assumes customer will deliver material for testing (if required) -- Warranty: 1 Year mechanical parts (electrical controls excluded) -- This quotation is valid for 30 days.

$29,800

LHI MBR-10 ROLL FEED GANG RIPSAW: Saw arbor with 25 HP arbor motor (30 HP and 40 HP available, see Options for pricing).Specifications: -- 1-15/16" Saw arbor bearings and 10" usable arbor. 12" useable arbor available. Uses 12" dia. x 1-3/4" bore saw blades. -- 1/8" to 2" Max. cutting depth on hardwoods and softwoods; 18" minimum stock length; 17" maximum stock width; removable and replaceable phenolic throat plates. -- Unique “swing down arbor frame"; for easy and fast blade changing. Blades are positioned using spacers.Feed system with: -- (2) 1 HP Feed motors with constant feed speed to be determined from thickness of wood, type of wood, and maximum number blades (average speed is set at 80 FPM). -- (6) Non-marking steel drive rollers; top and bottom rolls are powered for superior feeding capabilities; hand crank for easy feed roll height adjustment. -- Includes safe, fully enclosed belt and chain guards and double anti-kickback device. Features: -- Simple design, low cost, high performance. -- High production, fast setup, workhorse. -- Off-The-Shelf Parts are found locally for ease of maintenance.Options: -- 30 HP arbor motor & starter, add $1,150, -- 40 HP arbor motor and starter, add $2,300, -- Variable Speed Drive with speeds from 10 to 100 FPM, add $2,450. -- 12" Useable arbor space, add $2,950. -- 12" x 24T Blade,1.75" Bore, $115 each. -- 12" x 30T Blade,1.75" Bore, $165NOTE: PRICING DOES NOT REFLECT Mfg's 7% MATERIALS SURCHARGE