704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1891 Results Found

704-841-2001

LHI RFPR 72/12 "HEAVY DUTY" MULTI-BLADE PANEL SAWSpecifications -- (1) 50 HP main arbor motor for 1/8" min. - 2" max. material thickness; 12" Dia max. blade capacity with 1.25" minimum spacing between the blades; Minimum panel length 30" & 72" of usable width cutting capacity. -- 3-15/16" Dia. arbor with 1-15/16" precision arbor bearings; positive powered steel contact feed rollers with (8) Polyurethane drive rollers; variable feed speed to max 80 FPM. -- (1) "Quick Change" arbor cart trolley and blade box for 9 1/2" cutsOn average this machine will cut a bundle (42 sheets) of 3/4" Plywood. LVL, PB, MDF or OSB into narrow strips in 4 minutes or less.Available Options: -- Blade Box Arbor Cart and Trolley $ 12,590.00 each -- Arbor Carts modifications to accept 12" dia. blades $ 700.00 each -- Single Point Height Adjustment $ 6,000.00 each -- "Quick Change" set up kit (includes belt guide, belt tensioner, and hydraulic arbor lock) $ 3,695.00 each -- Tandem 8000# capacity infeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt, 31" x 192" platform and cross bars for fork truck entry $ 14,495.00 each -- Tandem 8000# capacity outfeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt with 48" x 192" platform and beveled crossbars for fork truck entry and auto down indexing $ 16,390.00 eachTooling Cost: -- Carbide Tip Blades 12" x 40T x 4 3/16 bore with TCG and 3 pin holes $ 125.00 each -- Saw Blade Tooling Collars $ 125.00 each -- Actual Model is LAUDERDALE-HAMILTON RFPR "HEAVY DUTY" 12 Panel Rip SawNOTE: PRICING DOES NOT REFLECT FACTORY'S 7% MATERIALS SURCHARGE

$239,800

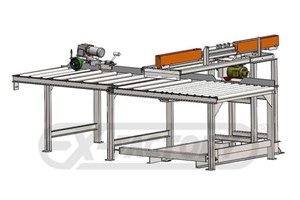

LHI 96" x 60" ANGULAR TYPE RIP & CROSS-CUT SYSTEM: Specifications: -- Automatic Angular Rip & Crosscut 5-Position System; max. panel size of 8' (96") long x 5' (60") wide x 1" - 4" thick; 1.25" minimum spacing between the blades; variable feed speed from 0 - 150 FPM. This system will process a unit of material in approx. (7) Min. -- Pos. # 1: LHI Automatic Staging/Infeed/Transfer & Panel Rake Feeding System: 10' (120") Long, powered 3-chain staging conveyor; (2) units can be preloaded while (1) unit is in process. Automatic up-indexing 4,500 Lbs capacity Scissors Lift with auto. rake infeed system: infeed rake system designed with a thin material device that can automatically load material as thin a 1/8". -- Pos. # 2: LHI "72": 72" Arbor length designed for panels up to max. of 5' (60") wide, min. panel length 30"; 40 HP main arbor motor; 1/8" min. - 1" max. material thickness with no adjustment needed over a 3/8" thickness variation. 2-3/4" Dia. arbor with 1-15/16" "Fafnir" arbor bearings; positive non-marking steel contact feed rollers with (optional) poly-covering, driven from top & bottom. Includes: (6) blade collars; (2) 6" dia. vertical dust outlets with an easy access strip separator box. -- Pos. # 3: LHI Cross-Transfer System: Transfer conveyor with panel hold-down & chain drive system to change direction 90° & automatically feed LHI 102". -- Pos. # 4: LHI "102": 102" Arbor length designed for panels up to max. 8' (96") long; 30 HP main arbor motor; 1/8" min. - 1" max. material thickness with no adjustment needed over a 3/8" thickness variation; 2-3/4" dia. arbor with 1-15/16" "Fafnir" arbor bearings. Positive non-marking steel contact feed rollers with (optional) poly-covering, driven from top & bottom. Includes: (6) blade collars; (2) 6" dia vertical dust outlets with an easy access strip separator box. -- Pos. # 5: LHI Stacking & Outfeed Transfer System: Auto. down-indexing 4,500 Lbs cap. Scissor Lift; (4) adjustable alignment posts & (4) bin separators to keep processed stacks square. 98' (96") Long outfeed gravity conveyor.Operating System: -- (1) LHI ALLEN-BRADLEY "Inter-Link" PLC for simple single-operator management of the entire system from (1) central control.NOTE: ...Attached description & pictures are for INFO purposes only; ...a NEW System can be modified to your exact specifications!NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE

$43,600

LHI RFPR-72/10 MULTI-BLADE PANEL SAW: Specifications: -- 40 HP main arbor motor; 1/8" min. - 1-1/4" max. material thickness; 10" dia blade with 1.25" minimum spacing between the blades; -- 3-15/16" Dia. arbor with 72" of usable width cutting capacity, min. panel length 30"; -- 1-15/16" precision arbor bearings; positive powered steel contact feed rollers; -- Fixed feed speed of 80 FPM. Blades & collars: -- Thin kerf 10" dia x 40-tooth x 4.18" bore non-split blades with quick & easy setup for fast blade positioning/removal (blades not included). -- Blades & collars are sold separately & not included in the machine price; 10" dia. x 40-tooth thin kerf blades, please add ...$ 105 ea.;1.25" wide x 4.18" bore blade collars, add ...$ 145 each. Complete with: -- (2) 4" dia dust collection ports on top and (1) 8" dust collection port on bottom. Total recommended 2,200 CFM -- Actual Model is LHI RFPR-72/10 Roll Feed Panel Saw. Available Options at additional cost: -- 110 V Infeed Scissor Lift with foot pedal controls or automatic up-indexing; 110 V Outfeed Scissor Lift with automatic down-indexing;Assortment of blade thicknesses & diameters; Split blade & collar system; Additional Options Depending on application: -- Main motor power from 30 - 75 HP; 4" Max. cutting height (requires 75 HP motor); -- Variable feed speed; Non-marking Polyurethane contact feed rollers; -- Additional arbors; "QUICK CHANGE" arbor system (see video); -- "Pigtail" quick change Crosscut Saw System.Many more tooling & configuration options available upon requestThis machine will cut a bundle (42 sheets) of 3/4" Plywood. PB, MDF or OSB into narrow strips in (4) minutes or less.NOTE: PRICING DOES NOT REFLECT FACTORY'S 7% MATERIALS SURCHARGE

$54,780

LHI RFPR 102/10 MULTI-BLADE PANEL SAW: with 102" of usable width cutting capacity. Specifications: -- (1) 40 HP main arbor motor for 1/8" min. - 4-1/4" max. material thickness; min. panel length 30"; 102" of usable width cutting capacity. -- 12" Dia max. blade capacity; 1.25" minimum spacing between the blades; -- 3-15/16" Dia. arbor with 1-15/16" precision arbor bearings; -- Positive powered steel contact feed rollers with (8) Polyurethane drive rollers; fixed feed speed of 80 FPM. -- Includes (6) arbor collars - blades not included. -- Complete with:(2) 4" dia dust collection ports on top and (1) 8" dust collection port on bottom. Total recommended 2,200 CFM.Available Options: -- Blade Box & "Quick Change" Arbor Cart and Trolley $12,590.00 each -- Arbor Carts modifications to accept 12" dia. blades $700.00 each -- Single Point Height Adjustment $ 6,000.00 each -- "Quick Change" set up kit (includes belt guide, belt tensioner, and hydraulic arbor lock) $3,695.00 each -- Tandem 8000# capacity infeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt, 31" x 192" platform and cross bars for fork truck entry $14,495.00 each -- Tandem 8000# capacity outfeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt with 48" x 192" platform and beveled crossbars for fork truck entry and auto down indexing $16,390.00 each -- Drag Chain Feeder Conveyor - Roller conveyor transfers sheets to in-feed of saw and dog chains align and start the sheets into the saw feed rolls. Recommended with 102" wide machines, $18,800 Tooling Cost: -- Carbide Tip Blades 10" dia. x 40-tooth thin kerf blades $125.00 each -- Saw Blade Tooling Collars $125.00 eachOn average this machine will cut a bundle (42 sheets) of 3/4" Plywood. LVL, PB, MDF or OSB into narrow strips in 4 minutes or less.NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE

LHI AUTOMATIC RAKE FEEDER with the following equipment: -- Panel Feeder with up to 18' Long x 5' Wide x 1" Thick Sheet Capacity (with 4' min. sheet length) -- Feeder loads from right side when viewed from the End of the Scissors Lift -- Auto-cycle for Rake Feeder -- 6' Line-Up conveyor with Fence & Powered Pinch Wheel -- 8000 Lbs. Tandem Scissors Lift with 5' x 17' top, 600-Volt, 3-phase, 2 HP motor -- 5-Section Gravity Rollers on Scissors Lifts -- 12' Powered 5 Strand Chain Conveyor Feeds Tilt Lift w/forward/ reverse, jog controls -- Wired for 600-Volt/3-Phase/60-Cycle Operation (other voltages available) -- Arranged for Customer Provided MultiScore Panel Ripper with right side arbor loading

$88,500

LHI MODEL RFPR ROLL FEED PANEL RIP SAWWith the following Standard and Optional Equipment: -- Roll Feed Panel Rip Saw - 72" Arbor - 50 HP motor -- 10 to 80 FPM (4-speed programmable or potentiometer) -- (8) Polyurethane feed rollers -- 10" Dia. blades (thickness-1/8" to 1-1/4") Infeed Scissors Lift 4,500 Lbs capacity -- 4' x 8' top -- (3) 2"; x 3"; support tubes for fork access -- 110 VAC / 1-Ph power unit -- Foot pedal control -- Automatic up-indexingOutfeed Scissors Lift 4,500 Lbs capacity -- 4' x 8' top -- (3) Support ramp/cross-bars to allow for access -- Auto down indexing -- 110 VAC / 1 Ph power unit -- Foot pedal controlSawblades: -- (10) 10" x 40T x 4-3/16 Bore, TGC Blades -- (10) Blade Collars, 3-15/16" ID x 4.18" bore x 1.25" wide Quick-change arbor setup with the second arbor: -- Arbor change cart (included with the arbor setup that comes with the saw to allow roll-out) Second Arbor Setup Includes: -- Cart -- Blade Box -- Arbor, Bearing -- Sheave -- Throat Plate Rack -- (6) Throat Plates Quick Change Kit: -- Belt Guide -- Belt Tensioner -- Hyd. Arbor Lock Quick Change Kit permits the operator to release the belt and unlock the arbor from the front side of the machine. Without the kit, the operator must open the rear guard to remove the belt and unlock the arbor -- (10) Blades for the second setup -- (10) Collars for the second setup 16-week ESTIMATED delivery: -- Delivery assumes order and down payment are received within (1) week of the date of quotation. Installation technical assistance for $115/Hr plus travel time and expenses Customer responsible for rigging Quote assumes customer will deliver material for testing (if required) Warranty: (1) Year mechanical parts (electrical controls excluded) This quotation is valid for 30 days. ESTIMATED DELIVERY DATE:The delivery date is quoted as 'estimated' because the equipment we manufacture is built to order and to our customer's specifications. This estimate is made under the assumption that there will be no interruptions of labor, material shortages, or any environmental or other unforeseen circumstances. LHI is not responsible for any installation or production costs resulting from actual delivery dates which exceed the quoted estimated delivery dates. Accurate dates for the delivery will not be available until the equipment is in the manufacturing phase. If there are custom features for the quoted equipment then accurate delivery dates will be available when testing is complete. Please consult with the factory for updates to the expected delivery date.NOTE: PRICING DOES NOT REFLECT FACTORY'S 7% MATERIALS SURCHARGE

$84,714

LHI MODEL RFPR ROLL FEED PANEL RIP SAW WITH THE FOLLOWING STANDARD AND SPECIAL EQUIPMENT: Specifications: -- 72" Useable Arbor and 50 HP Arbor Motor -- 14 - 80 FPM Variable Speed Feed Rate (4-speed programmable or potentiometer) -- (8) Polyurethane feed rollers -- Arranged for 14" dia. blades and 4"; max cutting thickness -- Single Point Thickness Adjustment from 1/2" to 4" -- Arbor Quick-Change KitComplete with: -- Additional Arbor Setup, Includes: Cart, Blade Box, Arbor, Bearings, Sheave, Throat Plate Rack, and (6) Throat Plates -- (15) Blade Collars: 3-15/16" ID x 4.18" bore x 1.25" wide -- (15) 14" Carbide Tipped Blades: 40 Tooth with 4.188 bore -- Delivery ESTIMATED at (14) weeks; assumes order and down payment are received within (30) days of the date of this quotation. -- Technical Installation assistance - $125/Hr plus travel time and expenses -- Buyer is responsible for rigging -- Quote assumes customer will deliver material for testing (if required) -- Warranty: 1 Year mechanical parts (electrical controls excluded) -- This quotation is valid for 30 days.

$29,800

LHI MBR-10 ROLL FEED GANG RIPSAW: Saw arbor with 25 HP arbor motor (30 HP and 40 HP available, see Options for pricing).Specifications: -- 1-15/16" Saw arbor bearings and 10" usable arbor. 12" useable arbor available. Uses 12" dia. x 1-3/4" bore saw blades. -- 1/8" to 2" Max. cutting depth on hardwoods and softwoods; 18" minimum stock length; 17" maximum stock width; removable and replaceable phenolic throat plates. -- Unique “swing down arbor frame"; for easy and fast blade changing. Blades are positioned using spacers.Feed system with: -- (2) 1 HP Feed motors with constant feed speed to be determined from thickness of wood, type of wood, and maximum number blades (average speed is set at 80 FPM). -- (6) Non-marking steel drive rollers; top and bottom rolls are powered for superior feeding capabilities; hand crank for easy feed roll height adjustment. -- Includes safe, fully enclosed belt and chain guards and double anti-kickback device. Features: -- Simple design, low cost, high performance. -- High production, fast setup, workhorse. -- Off-The-Shelf Parts are found locally for ease of maintenance.Options: -- 30 HP arbor motor & starter, add $1,150, -- 40 HP arbor motor and starter, add $2,300, -- Variable Speed Drive with speeds from 10 to 100 FPM, add $2,450. -- 12" Useable arbor space, add $2,950. -- 12" x 24T Blade,1.75" Bore, $115 each. -- 12" x 30T Blade,1.75" Bore, $165NOTE: PRICING DOES NOT REFLECT Mfg's 7% MATERIALS SURCHARGE

$132,700

LHI RFPR ROLL FEED PANEL RIPPER - "BUILT TO ORDER SYSTEM" with the following equipment: -- Ripsaw: -- 72" Arbor - 50 HP arbore motor and 14 to 80 FPM Variable Speed Feed Rate (4-speed programmable via VFD) -- (8) Polyurethane Feed Rollers -- Arranged for 10" dia. blades to rip panel thickness from 1/8" to 1-1/2"; -- Single Point Thickness Adjustment -- Quick-Change Arbor Kit Additional Arbor Setup Including: -- (1) Arbor Cart, (1) Blade Box, (1) Arbor Shaft, (1 set) Bearings, (1) Arbor Sheave, and (1) Throat Plate Rack Automatic Infeed System: -- 4,500 Lbs. Capacity Hydraulic Scissors Lift with (4) loading ramps to feed and align 4’ x 8’ sheets into Panel Saw -- 110VAC/1PH Scissors Lift power unit -- Auto-Cycling Rake Feeder -- 6’ Line-Up Conveyor With Power Pinch WheelOutfeed Scissors Lift: -- 4,500 Lb. Capacity Hydraulic Scissors Lift with 4' x 8' top, (3) support ramps/cross-bars to allow fork access -- 110VAC / 1Phase power unit -- Auto Down Indexing -- Auxiliary Foot Pedal Control Blades, Collars and Throat Plates: 10" x 40T x 4 3/16 Bore, TGC, $105 eachBlade Collars: 3-15/16" ID x 4.18" bore x 1.25" wide, $135 eachAluminum Throat Plates, $35 each TERMS AND CONDITIONS: -- Delivery: 16-18 Week ESTIMATED delivery date assumes your order is received within one week of date of this quotation. -- A 5% Tooling & Steel Surcharge to be added to the machinery price when the total is known -- Installation technical assistance, $125/hr. plus travel time and expenses (if required) -- Customer responsible for own rigging -- Quote assumes customer will deliver material for testing (if required) -- Warranty: 1-year mechanical parts (electrical controls excluded) -- FOB: Shannon, MS 38868. ESTIMATED SHIPPING DATE: 16 TO 18-WEEKS --The delivery date is quoted as “estimated"; because the equipment manufactured is built to our customer's specifications. This estimate is made under the assumption that there will be no interruptions of labor, material shortages, or any environmental or other unforeseen circumstances. -- LHI is not responsible for any installation or production costs resulting from actual delivery dates which exceed the quoted estimated delivery dates. Accurate dates for the delivery will not be available until the equipment is in the manufacturing phase. If there are custom features for the quoted equipment then accurate delivery dates will be available when testing is complete. Please consult with the factory for updates to the expected delivery date.NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE

$6,825

LHI 4,500 # Scissor LiftSimple Design, Low Cost, High Performance w/ Off-The-Shelf Parts so you can keep it running years from now Specification: -- 4,500 Lbs weight capacity. -- 48" x 96" Smooth steel platform. -- Lowered height 9-1/2" raised height 49". -- Travel speed: 1/2" per second up -- Foot pedal control.Available Options: -- Automatic Down Indexing -- Automatic Up Indexing -- Automatic Up/Down Indexing

$9,115

LHI 6,000 # Scissor LiftSimple Design, Low Cost, High Performance w/ Off-The-Shelf Parts so you can keep it running years from now Specification: -- 6,000 Lbs weight capacity. -- 48" x 96" Smooth steel platform. -- Lowered height 9-1/2" raised height 49". -- Travel speed: 1/2" per second up -- Foot pedal control.Includes: Auto-indexing UPAvailable Options: -- Automatic Down Indexing -- Automatic Up Indexing -- Automatic Up/Down Indexing

$52,733

LHI PIGTAIL Crosscut saw with conveyor and air stopSpecifications -- 62" Cut width --Saw motor 5 HP -- 14 FT gravity conveyor cutting surface -- Cam Lock adjustable stop -- Power feed wheel for rip saw infeed assist -- Blade dia. 12"Equipped with and Features -- 4,500 lb lift with loading ramps 1 HP, 30" X 72" platform -- 4,500 lb Outfeed lift with 3 ramps, 48" X 96" Platform, Auto down indexing -- 10" X 40T X 4-3/16" , 30 Blades -- 3-15/16" ID x 4.18" bore x 1.25" wide 30 collars -- 32 Throat Plates

$186,709

LHI 72" RFPR Wide Arbor Roll Feed Gang Panel Ripper with Custom 5' x 16' Automated Infeed -- Specifications: -- Panel Ripper with 30 HP Arbor Motor; 1/8" min. to 1-1/4" max. material thickness and 72" cutting width. -- Machine configured for arbor removal from the right side of the Saw when facing the Saw's Infeed (opposite of standard) -- Electricals arranged for 600-volt/60-cycle/3-Phase operation -- 10" Dia. blade design will cut thru max. 1-1/4" thickness; -- 3-15/16" dia. arbor with 72" of usable width cutting capacity, min. panel length 30". -- 1-15/16" FAFNIR arbor bearings; with (8) steel feed rollers on 6" centers; fixed feed speed of 80 FPM -- 47-1/4" working (passline) height -- (1) Arbor Cart is included -- (2) 4" Dia. dust collection ports on top and (1) 8" dust collection port on bottom. Recommended 1,500 CFM Includes the Following Optional Items: -- 5-Strand powered Chain Deck; 12' long; arranged to feed 5' x 16' packages onto the Scissors Lift. Complete with controls for forward, reverse, and jog. -- 5-Sections of Gravity Rollers on Scissors Lift Deck -- 8,000 lbs. Infeed Tandem Scissors Lift with 5' x 17' Deck and 2-HP, 3-Phase Motor. Lift includes a backstop for initial alignment at the Rake Feeder -- (8) Polyurethane Feed Rollers on 6" centers -- Variable Feed Speeds from 10 to 80 FPM. -- Rake Feeder for 16' long panels -- Auto-cycle for Rake Feeder. -- 6' Line Up Conveyor with Fence and Powered Pinch Roll Included Tooling: -- (36) Standard Saw Collars for Ripping -- (72) Standard 10" Sawblades for Ripping (Includes a spare set) -- (37) Standard Throat Plates for RippingQuick Setup Kit Included, Contains the Following -- Belt guide -- Belt Tensioner -- Hydraulic Arbor LockAdditional Arbor Setup Included. Contains the Following: -- Includes cart, blade box, arbor, bearing, sheave, throat plate rack, and(6) throat plates -- Blade Box -- Arbor -- Bearings -- Sheave -- Throat Plate Rack -- (6) Throat Plates SYSTEM TOTAL ............….……$174,495 7% ($12,214) materials surcharge on $174,495 = $186,709

Call for Price

LIGMATECH MPH 410/25/07 CASE CLAMP (SEMI-AUTOMATIC): -- Specifications:(1) Horizontal & (1) vertical interlocked pressure beam, each with electric push button control; 8-beam surface area eliminates need for pressure pads. -- Working capacity:9.8" - 98.4" (250 - 2,500 mm) Length; 9.8" - 27.5" (250 - 700 mm) depth, 12" - 55" (305 - 1,400 mm) height.Motorized horizontal & vertical beams can position simultaneously or individually during setup, vertical & horizontal interlocking pressure walls, each with (8) individual beams move parallel & square to the clamp frame.(2) Selectable clamping speeds of approx. 5 FPM (1.5 MPM) or 10 FPM (3 MPM) and adjustable pneumatic pressure regulator clutch system stops the beams at preset pressure resistance. -- Features & Operation:Manual switch setting, adjustable dwell timer opens clamp automatically; operator control panel built into left side of clamp; virtually a "plug-in-play" machine. -- Actual Model is LIGMATECH MPH 410/25/07.

$16,000

LIGMATECH ZHR 01 RETURN CONVEYOR for RH FEED Edgebander (e.g. Brandt, OTT) & LH RETURN to the operator. Function After panels come off a through-feed machines feed-track, they are transported via (4) powered take-up belt onto a 90° transfer section and returned back to the operator. Specifications: Working Length, 12" - 98" (300 - 2,500 mm) max., working width 5.9" - 40" (150 - 800 mm) max., panel thickness 0.3" - 1.6" (8 - 40 mm) max. and 100 Lbs (45 kg) max. weight. Variable Feed-Speed, 26 - 138 FPM (8 - 42 MPM); Approx. total length of 30'; (4) 1/2” W x 18" L Pickup arms, spaced 7", 8" & 14", take product from the edgebander and transport it to cross transfer conveyor section. Cross Transfer Section, 42-1/2" x 83" x 38-1/4” H, transfers material and drops it 2-1/2" onto roller transfer section, 42-1/2" x 83" x 35-3/4” H, which transfers material to a powered 31-1/2" x 17-1/2’ L x 34” H flat-belt conveyor, which transfers material to a gravity roller conveyor, 35” W x 6-1/2’ L x 32-1/2” H, with 2-3/8” Dia. Roller on 3-1/8” Centers to be received by the operator. Actual Model is LIGMATECH ZHR 01-R-055 & used with a BRANDT AMBITION 1870 (aka KDF870) Edgebander. CURRENCY NOTE: Negotiable Price is listed in U.S. Dollars.

$47,500

LIGNA 8X40 Multi-Blade Edger/Gang Saw. 40" Wide by 8" high opening. Specifications: -- Bottom saw edger with (5) blades. Powered by a 125 HP TEFC motor. -- Features stacked air cylinder setworks with independent shifting on (3) blades. -- Infeed table with pop-up chains and fence, outfeed rollcase. -- Includes: Powered infeed and outfeed steel roll conveyors.

Call for Price

LIMTECH ORION-510 Flat Table CNC Router with Tool Changer & Boring:5' x 10' Capacity, great for "Nested Base Manufacturing" or just about any type of 3-Axis work.Axes travel range & feed speed: -- X-Axis 61" (1,550 mm), Y-axis with 121" (3,073 mm) and Z-axis 11.8" (300 mm). -- Working Table: 61" (1,550 mm) x 121" (3,073 mm); includes (3) pop-up stops to aid in panel positioning & a manual valve controlled 6-zone special high flow vacuum table system. -- X- & Y-Axis speeds are 2,165 IPM and Z-axis is 1,000 IPM for quick traverse positioning that reduces total CNC machining time between cutting cycles. -- DELTA Servo drive powers the axes movement.Machine bed/base: -- The welded structurally engineered machine base provides a solid foundation for superior cut quality; the entire frame is stress relieved and heat treated. -- X-, Y- and Z-Axis travel: The moving gantry bridge travels on 1.2" (30 mm) thick hardened & precision ground rectangle linear guide slider-ways giving extra smooth movement for high speed traverse and accurate cutting. -- Tool gantry & bridge movement by 1" (25 mm) rack & pinion; the vertical Z-axis travels on precision ball screw for smooth consistent and highly accurate movement.Routing/Machining: -- (1) 12 HP (8.8 kW) Air cooled "HSD" Router spindle with: HSK Tool holders, variable programming speeds from 1,000 to 24,000 RPM. -- Tools are loaded into the "HSD" spindle by (1) 8-position, side mount on the fly tool changer carrousel . -- Tool heights can be set using the Tool Length Setting Gauge (included); machine uses ER-32 tool collets.Drilling/Boring: -- (1) 9-vertical drills spindle head in L-shape configuration for 32 mm contstruction hole & line boring.CNC Control & Operator Interface: -- The "SYNTEC" INDUSTRY CONTROL System, gives the operator an easy to use interface and the flexibility to customize to user specifications; is Network-ready via Ethernet and with USB flash drive. -- Features: Canned cycle, Tool length-diameter compensation, Work Coordinates-Offsets, Spindle-Feed rate overrides, Program size up to flash drive size, DNC or drip feed operation and Unlimited offset registrations. -- Compatible with virtually all CAD/CAM programming software on the market; you choose the software that best suits your needs.Complete with & Includes: -- Dust hood with 6" manifold connection; (4) HSK tool holders; Tool Length Setting Gauge; MPG hand held wheel remote. -- 235 CFM Dry Vacuum Pump; 7.5 kW (10 HP) Vacuum Pump with ON/OFF pre-plumbed to control pane. -- Other Features: Machine Central lubrication, Safety light beams and Automatic homing operation. -- Machine weighs approx. 8,000 Lbs; 15 CFM air consumption at 90 PSI; machine power supply is wired for 220 Volts, 60 Cy, 3-Phase.Includes: Installation & Training by Factory Technician, and (1) Year Parts & Labor Warranty.

Call for Price

LIMTECH ORION-512 Flat Table CNC Router with Tool Changer & Boring:5' x 12' Capacity, great for "Nested Base Manufacturing" or just about any type of 3-Axis work.Axes travel range & feed speed: -- X-Axis 61" (1,550 mm), Y-axis with 145" (3,700 mm) and Z-axis 11.8" (300 mm). -- Working Table: 61" (1,550 mm) x 145" (3,700 mm); includes (3) pop-up stops to aid in panel positioning & a manual valve controlled 6-zone special high flow vacuum table system. -- X- & Y-Axis speeds are 2,165 IPM and Z-axis is 1,000 IPM for quick traverse positioning that reduces total CNC machining time between cutting cycles. -- DELTA Servo Drive powers the axes movement.Machine bed/base: -- The welded structurally engineered machine base provides a solid foundation for superior cut quality; the entire frame is stress relieved and heat treated. -- X-, Y- and Z-Axis travel: The moving gantry bridge travels on 1.2" (30 mm) thick hardened & precision ground rectangle linear guide slider-ways giving extra smooth movement for high speed traverse and accurate cutting. -- Tool gantry & bridge movement by 1" (25 mm) rack & pinion; the vertical Z-axis travels on precision ball screw for smooth consistent and highly accurate movement.Routing/Machining: -- (1) 12 HP (8.8 kW) Air cooled "HSD" Router spindle with: HSK Tool holders, variable programming speeds from 1,000 to 24,000 RPM. -- Tools are loaded into the "HSD" spindle by (1) 8-position, side mounted on the fly tool changer. -- Tool heights can be set using the Tool Length Setting Gauge (included); machine uses ER-32 tool collets.Drilling/Boring: -- (1) Vertical 9-head spindle drills in L-shape configuration for 32 mm contstruction hole & line boring.CNC Control & Operator Interface: -- The "SYNTEC" INDUSTRY CONTROL System provides the operator an easy to use interface and the flexibility to customize to user specifications; Network-ready via Ethernet and USB flash drive. -- Features: Canned cycle, tool length diameter compensation, work coordinates-offsets, spindle feed rate overrides, program size up to flash drive size, DNC or drip feed operation and unlimited offset registrations. -- Compatible with virtually all CAD/CAM programming software on the market; you choose the software that best suits your needs.Complete with & Includes: -- Dust hood with 6" manifold connection; (4) HSK tool holders; Tool Length Setting Gauge; MPG hand held wheel remote. -- Vacuum Pump; 8 kW (11.5 HP) Vacuum Pump with ON/OFF pre-plumbed to control panel. -- Other Features: Machine Central lubrication, safety light beams and automatic homing operation. -- Machine weighs approx. 8,500 Lbs; 15 CFM air consumption at 90 PSI; machine power supply is wired for 220 Volts, 60 Cy, 3-Phase. Includes: Installation & Training by Factory Technician, and (1) Year Parts & Labor Warranty.

$42,900

LIMTECH ORION-512D Flat Table CNC Router with Tool Changer & Boring:5' x 12' Capacity, great for "Nested Base Manufacturing" or just about any type of 3-Axis work. -- Axes travel range & feed speed: X-Axis 61" (1,550 mm), Y-axis with 145" (3,700 mm) and Z-axis 11.8" (300 mm). -- Working Table: 61" (1,550 mm) x 145" (3,700 mm); includes (3) pop-up stops to aid in panel positioning & a manual valve controlled 6-zone special high flow vacuum table system. -- X- & Y-Axis speeds are 2,165 IPM and Z-axis is 1,000 IPM for quick traverse positioning that reduces total CNC machining time between cutting cycles. -- DELTA Servo drive powers the axes movement. -- Machine bed/base:The welded structurally engineered machine base provides a solid foundation for superior cut quality; the entire frame is stress relieved and heat treated. -- X-, Y- and Z-Axis travel: The moving gantry bridge travels on 1.2" (30 mm) thick hardened & precision ground rectangle linear guide slider-ways giving extra smooth movement for high speed traverse and accurate cutting. -- Tool gantry & bridge movement by 1" (25 mm) rack & pinion; the vertical Z-axis travels on precision ball screw for smooth consistent and highly accurate movement. -- Routing/Machining:(1) 12 HP (8.8 kW) Air cooled "HSD" Router spindle with: ISO 30 Tool holders, variable programming speeds from 1,000 to 24,000 RPM. -- Tools are loaded into the "HSD" spindle by (1) 8-position, rack style tool station mounted on the end of the machine bed. -- Tool heights can be set using the Tool Length Setting Gauge machine uses ER-32 tool collets. -- Drilling/Boring:(1) 9-Vertical drills spindle head in L-shape configuration for 32 mm contstruction hole & line boring. -- CNC Control & Operator Interface: The "INTEK" INDUSTRY CONTROL System, gives the operator an easy to use interface and the flexibility to customize to user specifications; is Network-ready via Ethernet and with USB flash drive. -- Features:Canned cycle, Tool length-diameter compensation, Work Coordinates-Offsets, Spindle-Feed rate overrides, Program size up to flash drive size, DNC or drip feed operation and Unlimited offset registrations. -- Compatible with virtually all CAD/CAM programming software on the market; you choose the software that best suits your needs. -- Complete with & Includes:Dust hood with 6" manifold connection; assorted ISO 30 tool holders; Tool Length Setting Gauge; MPG hand held wheel remote. -- 15 HP Vacuum Pump; with ON/OFF pre-plumbed to control panel. -- Other Features:Machine Central lubrication, Safety light beams and Automatic homing operation. -- Machine weighs approx. 8,500 Lbs; 15 CFM air consumption at 90 PSI; machine power supply is wired for 220 Volts, 60 Cy, 3-Phase.

$35,000

100 HP - 1800 RPM Belt driven. -- Jacketed water-cooled requiring 14 Gpm. -- All stainless wetting surfaces and replaceable stainless tools. -- 24" Inside diameter x 102" inside length. -- 14-1/2" x 18" inlet and 12" x 30" outlet. -- Capacity rating is 6,600 to 26,400 pounds per hour at 6 pound density.