704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1911 Results Found

704-841-2001

Call for Price

//This machine is in an Auction on exfactoryauctions.com// //Link to machine: http://exf.ac/i6d SECO SK-20BS 20" Vertical Band Saw Specifications: Actual throat 18-1/4". Table size 22-3/4” LR x 20-1/4" FB, with 45° Tilt. Max. height under guard 12". Blade length 155", Blade width 1". Wheel speed 800 RPM. Equipped with: 3 HP - 3,450 RPM Motor. 20” Rubber-covered cast aluminum wheels. Complete with: Work light.

$25,000

SELCO EBT 120 REAR LOAD, AUTOMATIC PANEL SAW: -- Specifications:175" (4,450 mm) Overall cutting length & 4.8" (122 mm) max. saw blade projection. 20 HP (15 kW) Main saw motor, 3.0 HP (2.2 kW) scoring motor. "DIGISET" electronic scoring blade adjustment from the PC. -- Saw Carriage:Variable saw carriage forward travel speed 0 - 426 FPM (0 - 130 MPM), return speed 426 FPM (130 MPM). -- Pusher Fence:Electronically controlled overhead program fence, rack & pinion drive, variable forward speed 0 - 262 FPM (0 - 80 MPM), return speed 262 FPM (80 MPM); both the saw carriage and pusher driven by AC brushless Servo motors. --(8) Gripper Clamps (open up to 127 mm), of which (4) are closely spaced in crosscut area and the other (4) are at equal distance in rip cut area. -- Operator Interface:PC front end with Selco "NC 500" + Windows "XP" operating system; 15" flat screen control panel, standard keyboard, on-board optimization (displays cutting dimensions & patterns), possible tele-service diagnostic via telephone line, data input by keyboard or possible direct downloading from office PC. -- Rear Load System:Automatic rear loading lift table; 177" (4,500 mm) x 87" (2,200 mm) max panel size; 28.75" (730 mm) max. Stack height (max. stack height with pit or risers 812 mm / 32"); 10,000 Lbs (4,500 kG) cap. with 4 HP (3 kW) motor for raise-and-lower, encoder controlled guide rods for automatic book height adjustment. -- Rear of Machine:(3) Lateral aligners to accurately position book of panels on rear saw table prior to cutting; modular roller rear machine table with (12) roller track modules, side aligning device cross aligners to accurately position book of panels against the right angle fence prior to crosscutting. -- Complete with:90" (2,300 mm) Long crosscut fence (front-to-back), (2) side/crosscut aligners, "Quick Change" saw blade replacement system. --(4) Front mounted air flotation table with rounded front 24" x 80" (650 x 2,050 mm); rear of machine enclosed for safety. -- NOTE: Forward pusher speed for this machine is currently set at 82 FPM (25 MPM), return speed currently set at 197 FPM (60 MPM) according the CE safety standards. -- Actual Model is SELCO EBT 120 L ACTIVE 4500/2200.

$110,000

SELCO WNT 7/730 REAR LOAD, AUTOMATIC PANEL SAW -- Specifications: 177" (4,500 mm) Overall cutting length, 5" (127 mm) max. saw blade projection, 29 HP (22 KW) main & 3.5 HP (2.6 KW) scoring motor. -- Saw Carriage:Variable saw carriage speed from 0 - 606 FPM (0 - 185 MPM), return speed 600 FPM (185 MPM); Rack & pinion drive, driven by AC brushless Servo motors. -- Pusher Fence:Electronically controlled overhead program fence with (8) pneumatic gripper clamps (open up to 5" / 128 mm).Forward speed of 295 FPM (90 MPM) & return speed of 295 FPM (90 MPM); rack & pinion drive, driven by AC brushless Servo motors. -- Operator & Machine Control:PC front end with Selco "OSI" + WINDOWS "7" operating system with easy programming of very complex cutting patterns.15" Flat screen monitor displays REAL-TIME graphics of cutting dimensions & patterns, program cutting list, manual cuts, diagnostic & on-line help.Data input by industrial keyboard & mouse, floppy disk or CD; direct downloading from office PC is possible.OSI (Open Selco Interface) guarantees fully automatic management of cutting patterns by optimizing all machine movements (pressure beam, saw carriage and side aligner pusher positioning, etc.).The numerical control adjusts the optimum saw blade projection for the stack of panels being cut and sets the most appropriate cutting speed, in relation to the stack itself and, when necessary, to the width of trim cut too. -- Rear Load Lift Table:Automatic lift table 173" x 87" (4,400 x 2,200 mm), 12,000 Lbs (5,455 KG) lift capacity.4 HP (2.3 kW) Motor for raise-and-lower, encoder-controlled guide rods for automatic book height adjustment; 28.7" (730 mm) max book height w/o a pit or risers. -- Rear of machine:(3) Lateral aligners to accurately position book of panels on rear table prior to cutting.Rear modular roller support rails with 80 mm dia rollers; rear of machine enclosed for safety. -- Front of machine:Automatic side/crosscut aligning device located inside the pressure beam aligns the panels against the right angle fence prior to cross-cutting, 2.4" - 87" (60 - 2,200 mm) stroke.90" (2,300 mm) Long crosscut fence (front-to-back); (4) Front mounted air flotation tables with rounded fronts 26" x 81" (650 x 2,050 mm). -- Complete with: "Quick Change" saw blade system; "DIGISET" electronic scoring adjustment; Selco "Quick-Opti" optimizing software; CP link. -- Options Include:173" x 87" (4,400 x 2,200 mm), LH facing, rear in-feed/out-feed conveyors with fork cut-outs that allow for staging/loading/unloading from the Rear LH side of the machine. -- Actual Model is SELCO WNT 7/730/4500.

$21,500

SELCO - EB 70 L, ...CNC Front-Load Horizontal Beam CNC Panel SawSpecifications & Features -- 126" (3,200 mm) Overall cutting length, 2-3/4" cutting height (80 mm saw blade projection); 10 HP main & 3 HP scoring motor. -- Modular roller rear machine table; side aligning device for squaring ripped strips out to 59". -- Variable saw carriage travel speed from: 0 - 164 FPM (0 - 50 MPM). -- Electronically controlled overhead program fence; rack & pinion driven; forward speed of 80 FPM, 131 FPM return speed.Equipped with: -- (6) Clamps (open up to 70 mm - 2-3/4"); (3) are closely spaced in crosscut area & (3) are at equal distance in rip cut area; AC Servo motor drives on both saw carriage & pusher fence. -- PC Controller with: Graphics color monitor & "Assist Line"; LED readout integrated into "high tech" look operator control panel (displays cutting dimensions & patterns), (400) cutting patterns with (50) different dimensions for ea. pattern, self-diagnostic. Machine Features -- 1,500 mm (59") Long crosscut fence (front-to-back); (1) side/crosscut aligner. -- (1) Front mounted air flotation table in the crosscut area (24" x 80"), and (2) front mounted air flotation tables with patented rounded front for moving panel from rip to crosscut position (24" x 59" each). -- 36" Working height; rear of machine partially enclosed for safety.

Call for Price

SELCO EB 70 L CNC Front-Load Horizontal Beam CNC Panel SawSpecifications & features: -- 126" (3,200 mm) Overall cutting length, 2.75" cutting height (80 mm saw blade projection), 10 HP main & 3 HP scoring motor. -- Modular roller rear machine table, side aligning device for squaring ripped strips out to 59". -- Variable saw carriage travel speed from 0 - 164 FPM (0 - 50 MPM). -- Electronically controlled overhead program fence, rack & pinion driven, forward speed of 80 FPM, 131 FPM return speed.Equipped with: -- (6) Clamps (open up to 70 mm - 2-3/4"), (3) are closely spaced in crosscut area & (4) are at equal distance in rip cut area; AC Servo motor drives on both saw carriage & pusher fence. -- PC Controller with: Graphics color monitor & "Assist Line"; LED readout integrated into "high tech" look operator control panel (displays cutting dimensions & patterns), (400) cutting patterns with (50) different dimensions for ea. pattern, self-diagnostic. Machine features: -- 1,500 mm (59") Long crosscut fence (front-to-back), (1) side/crosscut aligner. -- (1) Front mounted air flotation table in the crosscut area and (2) front mounted air flotation tables with patented rounded front for moving panel from rip to crosscut position (24" x 59" each). -- 36" Working height; rear of machine partially enclosed for safety.

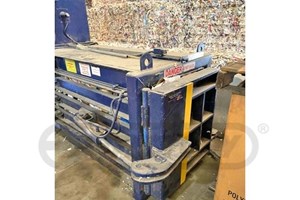

SELCO - HL50: Horizontal Closed Door BalerSpecifications: -- Large corrugated wide-mouth Baler. -- Horizontal Closed Door. -- Max. amps: Draw 48 amp; max. motor: 39 amp. -- Max HP motor: 30 HP – 60 Hz – 3 phase. -- Bale size: 72″ x 36″ x 48″. -- Feed opening: 50″ x 46″. -- Main pump: 800 PSI. -- Hydraulic pump capacity: 54 GPM. -- Oil reservoir capacity: 180 Gal. -- Cycle time: 20 Sec. -- Ramface pressure: 68 PSI. -- Baling material weight: 1,500 – 1,800 Lbs. -- Bale volume: 72 Cu. ft. -- Main cylinder: 7″ Bore; 62″ stroke. -- Door cylinder: 4″ Bore; 12″ stroke.

Call for Price

SELCO - HL-12-LH: Horizontal Baler with Infeed Conveyor• Motor: 20 HP. • Main Cylinder: 6";.• Hopper Opening: 50"; x 28";.• Cycle Time (No Load): 15 Seconds.• System Pressure: 2,000 PSI.• Total Compression Force: 56,556 Lbs.

Call for Price

SELCO HSO-128A50: Horizontal Auto-Tie Baler -- Type: Open end. -- Cylinder: 8". -- Motor: 50 HP. -- Infeed opening: 36" x 28-1/2". -- Bale size: 30" x 40" x Variable. -- Bale weight: Up to 1,200 Lbs (OCC). -- Production capacity: 2 to 4-1/2 TPH. -- Shear blade. -- Hopper size: 36" x 28-1/2". -- Ram face pressure: 103 PSI. -- System pressure: 2,400 PSI. -- Platen force: 120,637 Lbs. -- Cycle time: 11-1/2 Sec (no load).

Call for Price

SELCO - HLO-608-A40: Wide Mouth Auto-Tie Horizontal BalerSpecifications: -- Bale size: 48"; x 40"; x 72";. -- Main motor: 50 HP. -- Cylinder: 8". -- Twister motor: 2 HP. -- Cooler motor: 2 HP. -- (4) Tension cylinders: 5" Bore.Available NOW!

$17,500

SELCO EB 90 Horizontal Beam Panel SawSpecifications: -- 126" (3,200 mm) Overall cutting length, 122" (3,100 mm) pull back; 3.3" (85 mm) max. saw blade projection, 12 HP (9 kW) main saw motor, 2.4 HP (1.8 kW) scoring motor. -- Modular roller rear machine table, side aligning device, and (2) longitudinal aligners to accurately position book of panels on rear saw table prior to cutting. Equipped with: -- Variable saw carriage travel speed from 0 - 197 FPM (0 - 60 MPM), return speed of 197 FPM (60 MPM). -- Electronically controlled overhead program fence, rack & pinion driven, forward speed of 0 - 197 FPM (0 - 60 MPM), return speed of 197 FPM (60 MPM). -- (5) Clamps (open up to 85 mm); AC Servo motor drives on both saw carriage and pusher fence.CNi "NC 400 Plus" control with: Color monitor and "Assist Line" w/LED readout (displays cutting dimensions & patterns, virtually unlimited storage capacity of cutting patterns & different dimensions. "Assist Line" with: Real-time graphics, self-diagnostic, data input by keyboard or possible direct downloading from an office PC. Complete with: -- 90" (2,300 mm) Long crosscut fence (front-to-back), (2) side/crosscut aligners, "Quick Change" saw blade replacement system. -- (1) Front mounted air float tables with rounded front 24" x 79" (609 x 2,006 mm) & (2) 24" x 51" (609 x 1,295 mm) for moving panel from rip to crosscut position. -- Includes: -- (8) Rear roller module support rails; rear of machine enclosed for safety.

SELCO - HS0-128A, ...Horizontal Auto-Tie Baler -- Motor: 50 HP -- Cylinder: 8" -- Feed Opening: 36" x 28" -- Conveyor NOT included -- Loaded onto your Truck

SELCO - HLO-608-A40, ...Wide Mouth Auto-Tie Horizontal BalerSpecifications: -- Bale size: 48"; x 40"; x 72"; -- Main motor: 40 HP -- Cylinder: 8" -- Twister motor: 2 HP -- Cooler motor: 2 HP -- (4) Tension cylinders: 5" BoreEquipped with: -- Conveyor controls -- Shear bar (tapered & serrated)Available NOW!

SEVEIN - 12KVA, operates on 50 - 60 Hz, ...Transformer with Neutral wire (on 400 V side). -- General-purpose enclosed, European made, 12 KVA, 3-Phase ventilated Autotransformer. -- Primary 400 V, Secondary 208 - 220 V, 50 - 60 Hz.

SHENG-SHING - SDM-15 ...Wide Belt Sander (Open Ended)15" Single Head Wide Belt Sander with open end for up to 30 " capacity. -- Sanding Head: 15" Wide (30" cap. with 2-pass); 8" Helically Grooved Rubber Covered Contact Roll with 7.5 HP Drive. -- Features: 0" - 6" Part thickness cap., 2-speed conveyor feed 12 or 16 FPM; 16" x 48" Abrasive belts with air tensioning, pneumatic abrasive belt tracking.

SHENG-SHING - SDM-25, ...25" Wide Belt Sander1-Head; 24" width cap.; rubber-covered contact roll; approx. 10 HP motor. -- Abrasive belt size 25" x 48" with: Air tensioning & electronic abrasive belt tracking. -- 5-1/2" Max. height opening with: Manual raise & lower; variable feed speed drive. -- Complete with: Magnetic controls & dust outlet.

Call for Price

--This machine is in an Auction on exfactoryauctions.com-- SHODA MAXXIM 5' x 10' 2-Head CNC Router, with Vacuum Pump – Seller states that machine was run (1) shift from 2002 - 2006, then only a few days per year since! Specifications: Table size 63” x 122” x 29” H, with 3/4” Thick Top. Travels: X-Axis 133", Y-Axis 73", & Z-Axis 10". Max. machining feed speed 590 IPM. Max. positioning speed for X & Y-Axes 1,180 IPM. Equipped with: Moving single-zone vacuum table, with Extra-hard phenolic surface, Front-to-back configuration. (2) 12 kW (16 HP) - 18,000 RPM BT-30 Air-cooled electro-spindle, with Variable spindle speeds 3,000 - 18,000 RPM, AC Inverter, Dynamic spindle braking, Air/Oil mist lubrication. 16-Position Carousel-type automatic tool changer. Features: All Axes with Extra-large precision contour linear guideways. Closed loop AC Servo drives & Precision ground ball screws. Extended extra heavy-duty bridge for full 5' x 10 table coverage. Centralized lubrication system for all spindle & roller bearings, ball screws & guides. Operator Control: FANUC "SERIES 21i-M" Mobile CNC Control, with 10.4" Display, RS-232 Port, PCMCIA Slot, (3) Axes Simultaneous control, Manual pulse generator, Inch & Metric operation, Feed rate & Spindle speed override, Helical interpolation, Full cutter compensation, Background editing features, EIO/ISO recognition. Foot pedal control. Complete with: 2001 TRAVAINI "1-501V1A-460" 40 HP Vacuum Pump, S/N S1433, with Hour meter reading 17,003 Hrs. (10) Toolholders. Dust Manifold. Dimensions without Safety Rails: 202" x 155" x 110" H. Dimensions of Vacuum Pump: 82" x 36" x 65" H.

Call for Price

SHOP FOX W1678 Heavy Duty 26" 2-Head Drum SanderSpecifications: -- Heavy Duty 26" 2-Head Drum Sander. -- 24" Wide thick conveyor belt, similar to the ones used with Wide Belt Sanders. -- (2) drums 6" x 27-3/4". -- Enclosed fabricated steel base with easy access doors. -- 5 HP Single-phase motor that drives both sanding drums. -- 1st Head for coarse; 2nd head for fine sanding. -- Independent adjustment on both heads. -- Variable Speed conveyor , 0.25 HP feed drive. -- 0" - 4-1/4" Thickness cap. with manual hand wheel adjustment. -- (2) Each rubber covered infeed & outfeed rollers. -- (2) Dust outlets and push button magnetic controls.

Call for Price

Only 40 Hrs. Run Time! Shop Fox W1812 Planer Moulder Specifications: 12" Open-sided Mini Planer/Moulder offers smooth moulding and planing. 2 HP Motor belt drives head for 7,000 RPM spindle speed. Very smooth operation with a variable feed rate of 0-18 FPM. Cutterhead Diameter 1-1/4"² Max. material width 6.75"; also planes 7.5" wide. Easily handles material thickness from 1/4" to 7-1/2" max. 9" Min. stock length; max. profile depth 3/4" and max. profile width 6-3/4". Comfortable table working height of 31". Includes: Sturdy work "stand" Front-mounted On/Off controls. NOTE: Above specs are taken from literature and thought to be accurate. As always please take advantage of the inspection period to verify. Items seen in the background are NOT a part of this Lot.

$6,750

SHOP FOX W1738 WIDE BELT SANDER 37-1/2" Width cap. Combination HeadSpecifications --Single Head, 37" Wide Belt Sander with a combination head. -- 4" Dia. rubberized contact drum and finish platen for a fine finish to your work. -- Efficient 10 HP Sanding belt motor. -- Popular size 25" x 60" Abrasive belts. -- Reliable Air tracking for the sanding belt.Equipped with & Features -- Electronic digital readout for manual setting of conveyor bed. -- Better designed with (4) Jackscrews to move the conveyor bed from a 0" - 5-7/8" opening. -- Variable Conveyor speeds of 13 to 65 FPM. -- (2) Each infeed & outfeed spring loaded holddown rollers.

Call for Price

SHRED-TECH - ST50, ...Dual Shaft ShredderSpecifications: -- Motors: (2) 20 HP. -- Cutter width: 1" Approx. -- Cutting Chamber: 20" x 35". -- Control Panel. -- Mounted on stand. -- Feed Hopper: 21" x 40" Opening.Can be shown under power.