704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1911 Results Found

704-841-2001

$38,900

MAKOR LTSI/6 Profile Sander(6) Stations, 6"Width Capacity (approx), PLC Controller. -- 5.5HP Variable Speed Feed Motor with (6) 6"W Powered Feed Belts. -- 1st Station: Tiltable 3-Point Oscillating Profile Sander, 24" Contact Sanding Area, 2HP MAKOR Motor with Cooling Fan and J1000 Drive. -- 2nd Station: Tiltable 3-Point Oscillating Profile Sander, 24" Contact Sanding Area, 2HP MAKOR Motor with Fan and J1000 Drive. -- 3rd Station: Tiltable Polishing Head 2HP MAKOR Motor with Fan and J1000 Drive. -- 4th Station: Tiltable Polishing Head with with 2HP MAKOR Motor with Fan and J1000 Drive. -- 5th Station: Tiltable Polishing Head with 2HP MAKOR Motor with Fan and J1000 Drive. -- 6th Station: Tiltable Polishing Head with 2HP MAKOR Motor with Fan and J1000 Drive.Dimensions are 20’ L x 5’ W, 8’ H, and weighs approximately 7,000 lbs.

$33,900

MAKOR LTS/6E Profile Sander(6) Stations, 6"Width Capacity (approx), PLC Controller. -- 5.5HP Variable Speed Feed Motor with (6) 6"W Powered Feed Belts. -- 1st Station: Tiltable 3-Point Oscillating Profile Sander, 24" Contact Sanding Area, 2HP MAKOR Motor with Cooling Fan and J1000 Drive. -- 2nd Station: Tiltable 3-Point Oscillating Profile Sander, 24" Contact Sanding Area, 2HP MAKOR Motor with Fan and J1000 Drive. -- 3rd Station: Tiltable Polishing Head 2HP MAKOR Motor with Fan and J1000 Drive. -- 4th Station: Tiltable Polishing Head with with 2HP MAKOR Motor with Fan and J1000 Drive. -- 5th Station: Tiltable Polishing Head with 2HP MAKOR Motor with Fan and J1000 Drive. -- 6th Station: Tiltable Polishing Head with 2HP MAKOR Motor with Fan and J1000 Drive.

Call for Price

MURPHY-RODGERS - MRSE-14-RAL: Baghouse Dust CollectorSpecifications: 14" Inlet dia.; 4,836 CFM; (63) bags with: 520 Sq./ft. filter area; 9.3:1 air-to-cloth ratio; 20 HP fan motor; primary separator built into unit; secondary separation of fine particles by filter bag section; -- Equipped with: -- Rotary Air Lock. -- Fully automatic shaker controls with: Electric shaker as standard; consists of panel box with shaker starter; transformer for 115 V circuitry; solid-state timer for fan deceleration & shaking cycle. -- All necessary relays and internal wiring inside the panel box.

7.5 HP TEFC BALDOR Motor, 2,960 CFM at 6" W.G., free-standing interior unit, designed for (6) filter bags mounted over two plastic waste bags or barrels for waste collection. -- 10" Inlet dia.; 128 sq. ft. filter area, 66 cu. ft. storage cap.; quick clamp barrel removal. -- It comes with barrels and bags as shown. -- Overall height is 129"; requires 26" x 108" floor space..Magnetic Starter included

Call for Price

MURPHY-RODGERS MRSE-24 RAL Dust Collector Loaded with features -- General Data: Self-contained baghouse, approx 15,000 CFM with 1,913 sq. ft. of filter area based on 7.8 to one Air-to-Cloth-Ratio. -- Fan/Motor: 40 HP Baldor motor, 22" dia. inlet, primary separator built into the unit, secondary separation of fine particles by filter bags. -- Equipped with: 16" dia. bottom dump outlet controlled by a Rotary Air Lock with approx. 18" dia. discharge outlet. -- Complete with: (2) Electric motor driven automatic bag shakers, angle frame truck height support stand with walkway platform and full height ladder to access top of unit. Fan/motor mounted on top of the collector -- Includes: Magnetic Starter, Control Panel, Silencer, and Explosion doors. -- Approx. dims.84" x 85" x 32' High; 6,100 Lbs

Call for Price

MURPHY-RODGERS MRJ-610-122 Pulse Jet Dust Collector with Rotary Air Lock and Transfer Fan.Specifications: -- 8,500 CFM approx. @ 9 to 1 air to cloth ratio baghouse dust collector with (60) 10-feet long filters; total cloth area of 943 sq. ft. -- Filter Cleaning: Continuous Self-cleaning Using Compressed Air. -- Main Fan: 30 HP top-mounted blower motor. with approx 18" dia. inlet. --System includes: Relay/Transfer fan, steel structure support stand, low height as waste is transferred by fan, safety ladder/platform, top safety railing, and approx. 16" Rotary Air Lock.Actual model is MRJ 610 -122.

MURPHY-RODGERS MRZ 17/16L Interior/Open 6 Bag Dust Collector with Auger and Rotary Air Lock General specs: Approx. 7,600 CFM @ 8" SP. (6) top filter bags @ 24" dia. by 72" long. (6) bottom disposable plastic dust storage bags. -- Fan/Motor: 25 HP BALDOR TEFC motor direct driven fan with electrical starter. 17" diameter inlet, with lifting hooks. The bag collector motor is brand new and has never been powered on or fired up. -- Comes with: Main approx. 17" dia trunk line, shut-off, and Quick clamp removal for filter and plastic bags. -- All steel construction with rugged support legs. Air Deflectors allows operator to adjust the air flow and amount of waste evenly into the 6 waste bags. -- Note: NFPA 664 (Fire Code) states that a max. of 5,000 CFM is limit allowed for indoor enclosure-less dust collectors.

$49,500

NANXING NCG 2512L CNC FLAT TABLE MACHINE (W/LOADING/UNLOADING) + Auto Label Printing Application: -- Specifications:Bridge Gantry with 4' x 8' "Matrix" grid Phenolic surface table for "Nested Base Manufacturing", Automatic Loading and Unloading System with Vacuum cups & Sweeping Arm.Loading flow from Left to Right configuration. -- Work area:"Matrix" grid Phenolic surface flat table designed for "Nested Base Manufacturing". -- Working cap.:"X" Axis is 98.4" (2,500 mm), "Y" axis is 48" (1,220 mm) & "Z" axis is 9.8" (155 mm);Max. programmable speed: "X" & "Y" Axis 98 FPM (30 MPM), "Z" axis 65 FPM (20 MPM). -- Boring Unit:(10) Independent vertical boring spindles with (5) spindles in "X" axis & (5) spindles in "Y" axis, for 10 mm tools max dia. and 35 mm max. bore and 32 mm OC; -- Machining:(1) 12 HP (9 kW) Vertically mounted HSD electro-spindle router with HSK-63F adapters, Inverter controlled variable spindle speed up to 24,000 RPM, with max. torque from 12,000 RPM.(1) 8-Position Automatic tool changer with "revolver type" ATC tool plate. -- Operator & Machine Control: "SYNTEC" Controller, English language cutting/optimizing software, MS-Windows "10" based technology,32-bit Pentium - 400 MHz processor (w/operating system for Windows 7), 4 GB hard drive,15" Dell, international keyboard, soft-touch keypad & industrial mouse and USB port. -- Complete with:(2) 7.5 HP (5.5 kW) air-cooled vacuum pumps that provide 5,650 cu.ft./hr. (160 m3/hr.) of suction power: Safety & Emergency stops: Automatic lubrication system for guides & ball screw: Auto-Transformer for voltages between 200-600 V: -- Options Include: (1) NC Controlled infeed Scissor Lift table with vacuum loading Automatic Label Printing Station with Automatic Material Alignment (1) Rake system (1) NC controlled & powered flat belt outfeed table with vacuum sweeping system Tool Touch-Off Probe with automatic program update according to the tool length. Actual Model is NANXING NCG 2512L

$7,700

NASH 50-72 Spindle Sander(10) Spindles, 72" chucking cap., 3/8" - 6" dia. range;Specifications: -- 2-1/4" Dia. main arbor with long keys for driving head & tailstock wheels. -- Variable spindle speeds from 700 - 3,000 RPM, 7.5 HP spindle motor, 2 HP feed & oscillation rack motor, variable oscillating speed (60 - 120) strokes/Min, oscillating stroke adjustable up to 2" in length. -- (5) 72" Sanding racks, self-adjusting & oscillating. -- Equipped with: Overhead mounted dust hood, push-button control panel; production rate of (10 - 30) pieces/Min. -- Includes: brushes and sandpaper

$4,900

NASH 45-72 Spindle Sander(4) Spindles, 4" min to 72"max/. chucking cap., 3/8" - 6" dia. range;Specifications: -- 2-1/4" Dia. main arbor with long keys for driving head & tailstock wheels. -- Variable spindle speeds from 700 - 3,000 RPM, 7.5 HP spindle motor, 2 HP feed & oscillation rack motor, variable oscillating speed (60 - 120) strokes/Min, oscillating stroke adjustable up to 2" in length. -- (5) 72" Sanding racks, self-adjusting & oscillating. -- Equipped with: Overhead mounted dust hood (to be verified), push button control panel; production rate of (10 - 30) pieces/Min. -- Includes: brushes and sandpaper.

Call for Price

NEDERMAN S-1000 BAG FILTER Dust Collector. The NEDERMAN S-Series Baghouse Dust Collector is quick to install and easy to operate. It's the ideal solution for a smaller shop or single work-cell operation.Specifications: -- With a 10 HP motor and a 5,000 CFM @ 7" WG and 360 Sq/ft of filter media. -- 10 HP - 1,750 RPM TEFC Motor, (24) Beane material filter bags and magnetic starter. -- Features: Easy installation, typically (1) hour; quiet operation, (3) waste discharge points. Inlet opening 16". -- Resonable amount of pipe is included.

NEDERMAN S-750 BAG FILTER Dust Collector. The NEDERMAN S-Series Baghouse Dust Collector is quick to install and easy to operate. With a 7.5 HP motor and a 4,500 CFM @ 6" WG it's the ideal solution for the small shop or single work-cell operation. -- Specifications: 7.5 HP - 1,750 RPM TEFC Motor, (24) Beane material filter bags and magnetic starter. -- Features: 243 Sq/ft of filter media, easy installation, typically (1) hour; quiet operation, (3) waste discharge points. Inlet opening 11". -- Available in 208/230 or 480 V, 60 Cy, 3 Ph. Must specify voltage at the time of orderAvailable options:42 Gallons Drum Discharge - Single Drum (3 REQUIRED)230 Gallon Dump Bin

NEDERMAN S-500 BAG HOUSE DUST COLLECTOR. -- Open Bag house designed for interior application; 5 HP TEFC material fan motor, 1,750 RPM; free standing 2,000 CFM open frame bag house, 162 sq. ft. of filter area via (16) beane material filter bags; 7.5" W.G. static pressure. -- Bottom discharge into (2) plastic waste collection bag. -- Includes: Side-mounted blower assembly with support legs; (2) quick disconnect clamps for the plastic bags. Starter motor with push buttons. Option:42 Gallons Drum Discharge, Single Drum (2 REQUIRED FOR COMPLETE S-500)

NEDERMAN S-1000 BAG FILTER Dust Collector. The NEDERMAN S-Series Baghouse Dust Collector is quick to install and easy to operate. It's the ideal solution for a smaller shop or single work-cell operation.Specifications: -- With a 10 HP motor and a 5,000 CFM @ 7" WG and 360 Sq/ft of filter media. -- 10 HP - 1,750 RPM TEFC Motor, (24) Beane material filter bags and magnetic starter. -- Features: Easy installation, typically (1) hour; quiet operation, (3) waste discharge points. Inlet opening 16". Available in 208/230/460 V, 60 Cy, 3 Ph. Must specify Voltage at time of orderAvailable option:- Aluminum Impeller: - 45 Gallon Drum Discharge - Single Drum (3 REQUIRED)- 230 Gallon Dump Bin: Available spare parts:- Filter Bag (24 Filters)- Plastic Bags (Roll of 90 - 8 mil thickness) - 500mm Clamp (bags, barrels, and bin)

$18,000

Newman HP-688 Twin Bay Hydraulic Cold Press6-Sections (top platens) each 24" x 30" each, Center posts between third and fourth platens, creating two overall areas of 30" x 74". Specifications: -- Max. fixed opening 48" with 11" cylinder stroke, each platen section has (1) 10" bore with 5" dia. ram cylinder; -- Each platen is 15/16″ thick and it’s back structure is webbed every 5-1/2″ X 7-1/2″. -- Side-mounted self-contained hydraulic system w/tank, 10 HP continuous operating pressure compensating pump. -- Hand-Valves to Cycle Individual Platens with pressure gauges for each platen. -- Idle Pop-Up Bed Rollers in the bottom platen for easy loading and unloading.Over all the press is in excellent condition, is extremely heavily built, and is also a beautiful impressive press in person.

Call for Price

This item is in an Auction on exfactoryauctions.com. Go here to view item: http://exf.ac/i6r NEWMAN S-248 24" x 8" Single-Sided Planer Specifications: Planing thickness 1/16” - 8”. Min. stock length 13”, 4” Butted. Infeed & Outfeed table sizes 24" W x 16-3/4” L. Feed speeds 20 - 100 FPM. Equipped with: 4” Dia. 4-straight knife cutterhead. Segmented serrated upper with 2” W Spring-loaded segments & (3) Solid steel lower feed rollers. Chip breaker, with 2” W Reversible spring-loaded segments.

NEWMAN - SS-24, ...Wood Shaving Mill -- Motor: 100 HP. -- Feed Opening: Up to 5" thick x 14" wide. -- Cutterhead: 24" Dia. x 14" width. -- Knives: (16) Per row x (7) rows; total: (112) knives. -- Some extra knives included. -- Loaded onto your truck.

$15,850

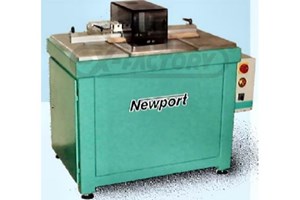

Specially designed haunching machine for beaded face frames, picture frames and decorative cabinetry. This machine uses a specially designed 2-piece carbide insert adjustable cutter. -- The work piece is placed on the table and against the fence and the cutter travels in a vertical motion to achieve the precision cut. -- Any size cut width is attainable by adjusting the width of the cutter and indexing from the fence stops. -- TECHNICAL SPECIFICATIONS -- Motors: 1 @ 1.1 KW (1.5 HP), Voltage: 220/440V/3/60hz, RPM: 6,000 RPM @ 60 hz, Air: 6 Bar, -- TOOLING: Insert Carbide: Milling head 140 mm (5.5"), Height min: no min., width 1/6" (4.2 mm). Max Profile: Height 3.5" (88.9 mm), width no max. -- Machine Dimensions: L x W x H - 40" x 30" x 35". Machine Weight: 675 lbs. -- AVAILABLE OPTIONS (Call for Pricing): Tooling carbide insert head, additional set of inserts, additional flip stops, foot pedal control, left & right digital fence.

Call for Price

---Liquidation Item---Palletized & Ready to Ship with Free Loading! 5,000 CFM 15 HP Enclosureless Baghouse Dust Collector https://exfactoryauctions.com/Detail/DC-230843/event/L051624$1

$2,800

NORTHFIELD - #4, ...Table SawSpecifications: -- 16" Dia. saw blade cap.; 7.5 HP - 3,450 RPM motor; 1" dia. arbor; 13/16" dado cap. with: Thin collar; blade tilts: 0° - 45°; 32" rip cap. with T-type fence.