704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1910 Results Found

704-841-2001

Call for Price

NEDERMAN S-1000 BAG FILTER Dust Collector. The NEDERMAN S-Series Baghouse Dust Collector is quick to install and easy to operate. It's the ideal solution for a smaller shop or single work-cell operation.Specifications: -- With a 10 HP motor and a 5,000 CFM @ 7" WG and 360 Sq/ft of filter media. -- 10 HP - 1,750 RPM TEFC Motor, (24) Beane material filter bags and magnetic starter. -- Features: Easy installation, typically (1) hour; quiet operation, (3) waste discharge points. Inlet opening 16". -- Resonable amount of pipe is included.

NEDERMAN S-1000 BAG FILTER Dust Collector. The NEDERMAN S-Series Baghouse Dust Collector is quick to install and easy to operate. It's the ideal solution for a smaller shop or single work-cell operation.Specifications: -- With a 10 HP motor and a 5,000 CFM @ 7" WG and 360 Sq/ft of filter media. -- 10 HP - 1,750 RPM TEFC Motor, (24) Beane material filter bags and magnetic starter. -- Features: Easy installation, typically (1) hour; quiet operation, (3) waste discharge points. Inlet opening 16". Available in 208/230/460 V, 60 Cy, 3 Ph. Must specify Voltage at time of orderAvailable option:- Aluminum Impeller: - 45 Gallon Drum Discharge - Single Drum (3 REQUIRED)- 230 Gallon Dump Bin: Available spare parts:- Filter Bag (24 Filters)- Plastic Bags (Roll of 90 - 8 mil thickness) - 500mm Clamp (bags, barrels, and bin)

NEWMAN - SS-24, ...Wood Shaving Mill -- Motor: 100 HP. -- Feed Opening: Up to 5" thick x 14" wide. -- Cutterhead: 24" Dia. x 14" width. -- Knives: (16) Per row x (7) rows; total: (112) knives. -- Some extra knives included. -- Loaded onto your truck.

Call for Price

This item is in an Auction on exfactoryauctions.com. Go here to view item: http://exf.ac/i6r NEWMAN S-248 24" x 8" Single-Sided Planer Specifications: Planing thickness 1/16” - 8”. Min. stock length 13”, 4” Butted. Infeed & Outfeed table sizes 24" W x 16-3/4” L. Feed speeds 20 - 100 FPM. Equipped with: 4” Dia. 4-straight knife cutterhead. Segmented serrated upper with 2” W Spring-loaded segments & (3) Solid steel lower feed rollers. Chip breaker, with 2” W Reversible spring-loaded segments.

$18,000

Newman HP-688 Twin Bay Hydraulic Cold Press6-Sections (top platens) each 24" x 30" each, Center posts between third and fourth platens, creating two overall areas of 30" x 74". Specifications: -- Max. fixed opening 48" with 11" cylinder stroke, each platen section has (1) 10" bore with 5" dia. ram cylinder; -- Each platen is 15/16″ thick and it’s back structure is webbed every 5-1/2″ X 7-1/2″. -- Side-mounted self-contained hydraulic system w/tank, 10 HP continuous operating pressure compensating pump. -- Hand-Valves to Cycle Individual Platens with pressure gauges for each platen. -- Idle Pop-Up Bed Rollers in the bottom platen for easy loading and unloading.Over all the press is in excellent condition, is extremely heavily built, and is also a beautiful impressive press in person.

$15,850

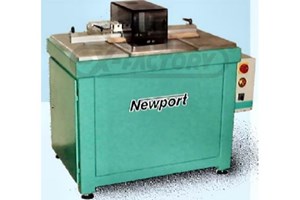

Specially designed haunching machine for beaded face frames, picture frames and decorative cabinetry. This machine uses a specially designed 2-piece carbide insert adjustable cutter. -- The work piece is placed on the table and against the fence and the cutter travels in a vertical motion to achieve the precision cut. -- Any size cut width is attainable by adjusting the width of the cutter and indexing from the fence stops. -- TECHNICAL SPECIFICATIONS -- Motors: 1 @ 1.1 KW (1.5 HP), Voltage: 220/440V/3/60hz, RPM: 6,000 RPM @ 60 hz, Air: 6 Bar, -- TOOLING: Insert Carbide: Milling head 140 mm (5.5"), Height min: no min., width 1/6" (4.2 mm). Max Profile: Height 3.5" (88.9 mm), width no max. -- Machine Dimensions: L x W x H - 40" x 30" x 35". Machine Weight: 675 lbs. -- AVAILABLE OPTIONS (Call for Pricing): Tooling carbide insert head, additional set of inserts, additional flip stops, foot pedal control, left & right digital fence.

Call for Price

---Liquidation Item---Palletized & Ready to Ship with Free Loading! 5,000 CFM 15 HP Enclosureless Baghouse Dust Collector https://exfactoryauctions.com/Detail/DC-230843/event/L051624$1

Call for Price

This item is in an Auction on exfactoryauctions.com. Go here to view item: http://exf.ac/i6q NORTHFIELD 12HD 12" Heavy-Duty Jointer Specifications: Max. depth of cut 5/8", Rabbeting cap. 5/8" x 12". 17” x 51-1/2” x 32-1/2” H. Outfeed table size 17” x 43” x 32-1/2” H. Equipped with: 3-1/2” Dia. 3-Knife Cutterhead. 5 HP - 1,735 RPM Motor. 52” L x 5-1/2” H Cast-iron fence, with 0° - 45° Tilt. Swing-away guard.

$2,800

NORTHFIELD - #4, ...Table SawSpecifications: -- 16" Dia. saw blade cap.; 7.5 HP - 3,450 RPM motor; 1" dia. arbor; 13/16" dado cap. with: Thin collar; blade tilts: 0° - 45°; 32" rip cap. with T-type fence.

NORTHTECH NT-EV-920RC Dual Head Wide Belt Sander2-Head Wide Belt Sanding Machine with 37" capacity. Specifications: -- First head 8-1/4" Dia. grooved rubber contact roll, with 20 HP motor. -- Second head: Combination finishing platen with grooved rubber roller and polishing pad, with 15 HP motor. -- Two (2) infeed and outfeed spring loaded holddown rollers; 2 HP variable speed feed drive. -- Sanding belt size: 37" X 85" and with electronic belt tracking. -- Motorized opening between conveyor bed and sanding heads. -- Ammeters for measuring motor loads. -- Includes spare abrasive belts.

NORTHTECH NT-KL-43-RC Wide Belt Sander (2) Heads;43" width cap. Drum, Combination Head.Head Configuration:1st Head: Rubber-covered contact drum with 25 HP motor2nd Head: Combination head with a rubber-covered contact drum and 2-1/4" wide finishing platen, 20 HP motor.Specifications: -- Thickness opening with PLC control, (DP-525 controller) keypad entry automatically adjusts to any thickness with LED readout. -- 37" x 75" Abrasive belts, TRU-TRAK solid state abrasive belt tracking. -- Variable feed drive 13 - 49 FPM, 2 HP motor. -- Endless belt conveyor, infeed and outfeed rubber covered pinch rolls. -- Complete with: 0" - 6" Automatic part thickness set up.Equipped with & Features: -- Infeed and outfeed rubber covered spring loaded holddown rolls. -- Feed emergency stops at infeed. -- Disc brakes on sanding heads, electrical interlocks on main access doors, and motor load meters. -- Note: Year of manufacturing has to be verified.

Northtech FR-200 Frame SawSpecifications: -- Saw capacity of 6" width x 8" vertical capacity. -- Minimum working 2"; high X 12"; long. -- Main drive motor to saw frame is 30HP 3PH, wired 460 --V servo drive system to feed works is 1/4HP 3PH, --Blower to saw frame rack for added cleaning value is 3HP 3PH, -- Body of frame saw is (2) sections allowing for fast access to the saw frame, -- Saw blade speed is fixed at 550RPM, -- Dust extraction requires min 3000 CFM and is arranged with (4) 5" ports, -- Blade size is standard with 500mm L x 40mm W x 0.9mm body in stellite or TCT tip,Equipped with & Features -- Digital electronic oiling system provides proper lubrication to the saw frame guides -- Vertical rail system which allows optimum cooling and long term durability, -- (4) guide blocks are thermo- censored to allow auto shut-off of machine should possible heat buildup occur.Machine dimensions 122"; L X 40"; WX, 79"; H weight 7100 lbs. Machine was new in 2007.

NORTHTECH - NT-KL-920-PRR- B & NT-KL-920 PRR-U, ...Top & Bottom 3-Head Planer Sander3-Head bottom with: Planer, drum and platen; 3-head top with: Planer, drum, and platen 920 mm (36") wide.Capacity: 36" x 5" thickness.SpecificationsBottom Machine Model: "NT-KL-920 PPR". -- Infeed driven Conveyor: 37" x 72" Long. -- 1st Head: Spiral cutterhead; (8) rows of 15 x 15 x 2.5 mm inserts carbide knives; (4) sides for rotation; low tool cost.Cutterhead: 175 mm (7") Dia. and 50 HP motor. Segmented chip breaker before the cutterhead. -- 2nd Head: Contact roller; (280 mm) 11" in dia.; 70 durometers, powered by a 40 HP motor; running at 3,600 FPM belt speed.Sanding belt size: 85" x 37". -- 3rd Head: 3-1/4" Pneumatic Polishing Platen; engineered as a combination station, air-cushioned & adjustable in pressure to various grits and materials application. Powered by a 30 HP motor. -- Lifting & lowering conveyor bed; 1-1/2 HP motor (includes auto. thickness setup device). -- Variable speed: 7.5 HP; inverter duty motor integrated with an AC inverter (VFD); control providing variable feed rate from 15 - 70 FPM for heavy calibration; LED readout feed speed indicator. -- Microprocessor Control for: Conveyor bed positioning to high precision via keypad entry. -- Automatic electronic preset panel thickness gauge/micrometer. -- Automatic Air Jet blast cleaning system on both sanding heads.Top Machine Model: NT-KL-920 PRR-U -- 1st Head - Spiral Cutterhead: (8) Rows of 15 x 15 x 2.5 mm inserts carbide knives; (4) sides for rotation; low tool cost.Cutterhead: 7" (175 mm) Dia.; 50 HP motor.Segmented Chip Breaker: Before the cutterhead. -- 2nd Head - Contact Roller: 11" (280 mm) Dia.; 70 durometers; powered by 40 HP motor; running at 3,600 FPM belt speed.Sanding belt size: 85" x 37". -- 3rd Head - 3-1/4" Pneumatic Polishing Platen: Engineered as combination station; air-cushioned & adjustable in pressure to various grits and materials application; powered by 30 HP motor. -- Lifting & lowering Conveyor Bed: Motor 1.5 HP (includes auto. thickness setup device). -- Variable speed 7.5 HP inverter duty motor; integrated with AC inverter (VFD) control; variable feed rate: 15 to 70 FPM for heavy calibration; LED readout feed speed indicator. -- Microprocessor Control: For conveyor bed positioning to high precision via keypad entry. -- Automatic electronic preset panel thickness gauge/micrometer. -- Automatic Air Jet blast cleaning system on both sanding heads. -- Powered dropdown Conveyor between Bottom & Top machine.Features (includes both machines) -- Massive monoblock base: 3/4" Thick plate steel weldments. -- Large dia. roller hold-downs; ball bearing supported; 65 duro UV rubber are standard features. -- Automatic soft start of main motors (Y-Delta). -- Disc braking/emergency shut down protection for: Sanding belt breaking, non-tensioned sanding belt; and mistracking of sand belt. -- All motors & electrics are CE-approved. -- Electronic oscillating belt tracking system. -- Au

$34,500

NORTHTECH NT-610EL Top & Bottom Planer:24" Wide x 7.5" thick capacity; 1/4" minimum thickness; 12" minimum stock length.Specifications: -- Cutterheads: 25 HP top head; 20 HP bottom head; 5,800 RPM on cutterheads; (6) row spiral insert cutterheads, Carbide knives 15 mm x 15 mm x 2.5 mm 4-sided -- Feed works: 3 HP variable speed feed with speeds from 20 to 75 FPM; 1 HP motorized raise and lower of bed; DP-525 digital thickness controller; Overhead carpet style feed system Equipped with & Features -- Sectional chip breaker; Hard chrome plated bed; Automatic lubrication for feed system; Amp load meter -- Dust Requirements: 3,800 CFM; (1)10" and (1) 7" dust outlet Seller states this machine has less than 600 Hours of use.

NORTHTECH - NT-SL2000XL, ...Straight Line Rip SawSpecifications: -- 20 HP Direct Drive Straight Line Rip Saw. -- 2" Arbor. -- Distance from column to blade: 18 in. -- Saw blade size: 10" - 14". -- 3-1/8" Cutting capacity. -- Glue Line Saw. -- Feed Motor: 1.5 HP. -- Feed Speed: 20 - 105 FPM.

Call for Price

Rigid one piece welded steel frame, with 10 HP direct drive spindle motor at 7,800 RPM, 1-1/4" x 4-1/2" stackable multi-cutter spindle to mill stile, rail & raised panel profiles. -- Stackable cutter spindle with push button indexing to significantly reduce set-up time as each station is preset; the change from one cutter to another is achieved via a select switch for each operation. -- Complete with: X - Y Sliding table w/pneumatic holddown. -- 2-way linear movement for straight or arch top doors up to 50" long. -- 5" Dust collection hood, and cutter shield. -- Includes: (1) Cathedral arch templates, (1) complete set of tools.

$1,450

NORTHTECH NT-6108ES-6 Edge SanderSpecifications: Sanding Belt is powered by a 3 HP 230/460V motor. -- The platen measures 6-3/4″ X 39″ and has NEW graphite. Rubber covered direct drive pulley. -- Equipped with: (1) 7-3/4" x 37" Adjustable side table and (1) 11-1/2" x 19" Adjustable end table; both side & end tables have vertical table travel w/hand wheel adjustment. Complete with: -- Magnetic controls with overload protection & dust hood with 4" dia. outlet.

Call for Price

//This machine is in an Auction on exfactoryauctions.com// //Link to machine: http://exf.ac/i5z NORTHTECH NT-EV-920RC DUAL HEAD WIDE BELT SANDER 2-Head wide belt sanding machine with 37" capacity. - Heads: 1st head: 8-1/4" Dia. grooved rubber contact roll, with 20 HP motor. 2nd head: Combination finishing platen with grooved rubber roller and polishing pad, with 15 HP motor. Two (2) infeed and outfeed spring loaded hold-down rollers; 2 HP variable speed feed drive. Sanding belt size: 37" X 85" and with electronic belt tracking. Motorized opening between the conveyor and sanding bed. Ammeters for measuring motor loads.

Northtech NT SLR-16SC Precision 16″ Straight Line Rip Saw FEED SYSTEM --Saw motor: 15HP, 3PH 230/460V -- Feed: 1.5HP variable from 40′ – 120′ FPMPRODUCT DIMENSIONS -- Min. thickness: 3/16″ -- Max depth of cut: 4-1/16″ with 16"; Blade -- Max depth of cut: 3-1/16"; with 14"; BladeSpecifications: -- Direct Drive = Direct Drive -- Feed Hp. = 1.5 Hp. -- Feed System = 4"; Split Chain with True Trac -- Feed Speed = 40-120 FPM -- Assisted Start = Wye Delt"; -- Throat Capacity = 18-1/4"; -- Min. Length = 12"; 2nd Roller to Kickback -- Min. Thickness = 3/16″ -- Max. Thickness = 4-1/16"; W/ 16"; BladeGlue Line Rip = Guaranteed 12′ 4/4 stock @ 50 FPMEquipped with & Features -- Blade Size = 14"; Tungsten Carbide Tipped -- Dust Collection = 1417 Total CFM -- Dust Port Out = 4"; Top 6"; Bottom -- Arbor Diameter = 2″ Arbor -- Idle Rollers = (8) Idle Rollers -- Hold Down Style = 8 Spring Loaded Hold Downs -- Kickback Finger = (59) Lower (32) Top -- Automatic Mechanical Oiler -- Low Oil Warning = Low Oil Shut-off -- Laser = 100mw Laser Light & Mount Bracket

NORTHTECH NT 1000-50HCVS Single-Sided 40" PlanerSpecifications: -- 40" Planer, 40 HP main motor, Helical Head, Adjustable bed rollers 15 mm x 15 mm x 2.5 mm Carbide Insert cutters. -- The spiral cutterhead provides a high chip removal rate, superior surface finish and low noise. -- Powerful 40 HP cutterhead motor makes this planer ideal for heavy-duty planing and meets high production requirements. -- Variable feed speed is mechanical variable from 0 - 90 FPM. -- Power elevation of the feed bed with "727 M Digital Table Adjustment" for fast accurate, and convenient thickness setting. -- Extra heavy rib reinforced cast iron table, surface precision ground. Equipped with: -- (4) Powered steel bed rollers. -- (4) Upper rollers. -- (2) Powered corrugated infeed rollers. -- (2) Powered urethane outfeed rollers. -- Upper and lower limit switches for opening control. -- (4) Dual 50 mm jack screws for raise/lower bed movement; 12" max opening. -- 2 HP Elevation motor with manual adjust. -- Rear E-Stop for added safety. -- Dual 6" dust ports requiring 1,000 CFM @ points of extraction.