704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2103 Results Found

704-841-2001

For dumping (1) load of fingerjoint blocks at a time. Hoist is fabricated from steel tubing with a box cradle that pivots at the top. -- 3-Sided cradle will hold the box, pallet, OR unit when it is pivoted up to 135° to the final dumping position; cradle opening is 88" long X 48" wide X 50" high . -- A pair of replaceable forks hold pallets in place in the cradle. The cradle is pivoted by a hydraulic cylinder driven by a 3 HP hydraulic pump. The hydraulic cylinder is manually energized by the fingerjointer operator with foot switches. -- Scope of supply includes all mechanical equipment, electric powered hydraulic pump, and two foot switches. All wiring by others.

ROSE GBUB-80 Glue-Bound Unit Breaker. Machine breaks the glue bond in a staggered stack of finger jointed material - see picture of material with the checkerboard end pattern. --Features -- Equalized Hydraulic squeeze, provides uniform load compression. --Hydraulic length change. Air operated Locking Pins on the Backstop Platen. --Backstop platen position indicator. --Simple manual controls for load length adjustment and crushing stroke on the control panel. --Heavy Duty Structural Steel Construction, Ease of Maintenance and Simple Operation (no cables).Does not use cables!Specifications: --Maximum opening is 16’-10"; for a single 4' x 4' x 16' unit. --Backstop Platen locks at 12" increments (2' minimum load length) --Pressure Platen, hydraulic actuated with 18" stroke. --Platen size 5' x 5' --5 HP Hydraulic Unit with a Pressure Compensated Pump (approx. 1 minute squeeze time) --Overall size approximately 5' x 25' x 7' high --480 VAC, 60 hertz, 3 phase, 30 ampsOptions: --10 HP hydraulic unit with approx. 30 second squeeze time, add $4,200 --Double unit capacity; crushes (2) 4' x 4' loads with 5' x 10' platen, add $19,700 --Automated Control Package with 2 Remote Controls for initiation of Pressing Stroke; Automatic open and hydraulic shut down; PLC Controls, automated load length adjustment with lighted indicators, add $ 7,400

ROSE BPUDH BOX, PALLET & UNIT DUMPING HOISTDescription: --Box, Pallet & Unit Dumping Hoist, for dumping one load at a time. --The hoist will be fabricated from steel tubing with a box cradle that pivots at the top. The three sided cradle will hold the box, pallet, or unit when it is pivoted up 135 degrees to the final dumping position. --A pair of replaceable forks hold pallets in place in the cradle. --The cradle will be pivoted by a hydraulic cylinder driven by a 3 HP hydraulic pump. The hydraulic cylinder is manually energized by the operator with foot switches. --Manufacture will supply all mechanical equipment, electric powered hydraulic pump, and two foot switches. --Cradle opening is: 168";L x 60";W x 60";H.Payment Terms: --50% with order, 40% prior to shipment, and the balance 10% net 30 days after receipt of equipment. Delivery is subject to the order file at the time the order is placed.Lead Time: --Delivery can be made in 12 weeks ARO at this time.Conditions: --The fabricated frames and appropriate parts of the items in this quotation will be painted with one coat of industrial grade Shady Lane Green enamel. Guards and appropriate moving parts will be painted Safety Orange. All gear-motors, mechanical equipment, limit switches, sensors or photoelectric devices as required for each item of this quotation, will be supplied and mounted. All pneumatic cylinders or other pneumatic power devices and their valves will be supplied and mounted. They will have connecting hoses and fittings installed. Filter/Regulator units will be supplied, mounted and connected by hose to the valves. Compressed air service to equipment is by others.Exclusions: --This proposal describes the machinery to be provided by Rose Machinery Inc. to the Buyer. The equipment supplied by Rose Machinery Inc. is specifically limited to the items actually described in the itemized detail pages of this quotation. Unless specifically mentioned herein, all other items and services are the responsibility of the Buyer. We do not include any state or local sales taxes, or any permit or other fees that may be required. All field wiring, plumbing, and installation is not included. Warranty: --Rose Machinery Inc. d.b.a. Complete Millwright Services, warrants all products of its manufacture to be free of defects in material, and workmanship, for a period of one year from date of shipment. Equipment provided by other manufacturers and incorporated within equipment manufactured by Rose Machinery will be warranted to the extent of the warranty provided by the respective manufacturer. Rose Machinery agrees to repair, or replace, at its option, any component found to be defective provided the purchaser promptly notifies Rose Machinery of the defect. Rose Machinery shall not be liable for incidental or consequential damages arising from said defective material. No other warranty written or implied is offered beyond that stated above unless specifically written and signed by an authorized a

Call for Price

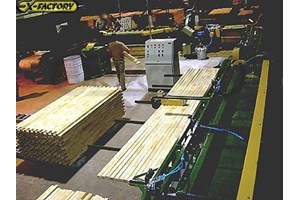

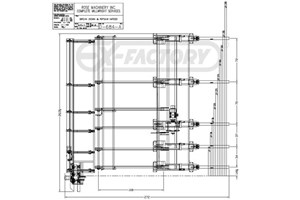

ROSE MACHINERY BDH/LC/LCFT Automated Infeed SystemAutomated, high speed Infeed System for Gang Rip Saws of all makes and models and other similar machines. -- 5-Arm Breakdown Hoist - Electric hoist accepts loads 4' wide x 4' high x 4' - 24' long; 10 HP gear motor (with brake) powers the hoist and holds the load. -- Hoist actuated through foot switches for up & down; limit switches provide max. up & down positions; (5) lifting arms tilt load at 50° allowing layers to spill onto the takeaway conveyor; 16,000 Lbs. max. lift cap. -- Landing Chain - Features: (6) Strands of roller chain; powered by a 5 HP gear motor at 60 FPM nominal rate. -- Tail end constructed with integral slide, stock transits from Breakdown Hoist; head shaft & gear motor supported by tubular steel frame with bolts to allow for leveling at installation. -- Material stops at the head end so the operator can flip & grade each piece. -- Chain races fabricated from steel, UHMW PE wear strips on the top race and on the return race; conveyor is 42' long. -- Magnetic motor starter with foot switch for operator to start & stop of the chain. -- Lateral Chain Feed Table "LCF2013-20": Feeds material 3" - 10" wide x 4' to 24' long x 1" to 3" thick; variable 50 - 200 FPM Feed rate; adjustable fence throughout 3/4" range for alignment with the Rip Saw (or other machines). -- (6) 30" long, low friction steel flattop infeed chains for long life non-marking transport; 1 HP gear motor. -- (3) Powered smooth steel & non-marking feed rolls, 2 HP gear motor; rolls & chains controlled by variable speed drives. -- (3) Overhead pinch rollers, 5" dia., urethane covered; 1st (2) pinch rollers powered by individual 2-1/2" bore air cylinders to singulate pieces onto a 2' bridge; 3rd roller keeps the board moving on the bridge; pinch rolls triggered by photoelectric cells. -- Note: Fabricated frames and appropriate parts of the items in this quotation will be painted with (1) coat of industrial grade Shady Lane Green enamel; guards and appropriate moving parts painted with Safety Orange. -- All gear motors, mechanical equipment, limit switches, sensors or photoelectric devices, as required for each item of this quotation, are supplied and mounted; all pneumatic cylinders or other pneumatic power devices and their valves supplied and mounted; connecting hoses & fittings installed. -- Filter/Regulator units supplied, mounted, and connected by hose to the valves; Note: Compressed air service to equipment is by others.

Call for Price

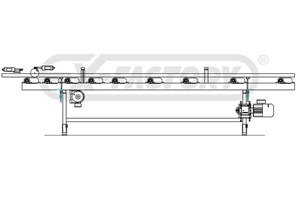

Ripsaw Feeder with 32" wide feed rolls on 18" thru 28" roll centers; will feed 3' thru 16' lumber. With 24" of in-out fence travel; feed speeds from 50 to 150 FPM; 3/4 HP feed roll drive and 3/4 HP fence drive via gear motor with brake. -- Fabricated frame of structural steel with boots that allow +/- 1" elevation adjustment. 3-1/2" dia. steel feed rolls driven by a variable frequency drive for speed adjustment; rolls are canted to aid in holding stock against the fence. -- Powered fence with 24" fence travel is easily shifted via joystick control for stock alignment with the sawblades. -- With pneumatic powered gate to keep material from feeding until the operator initiates the feed sequence. -- Urethane covered idler pinch roll is attached to the fence and is powered down at the start of the feed sequence. When a photocell detects the board is clear of the gate, the pinch roll and gate will return to their normal position. Electrical control panel ready for connection to the power supply.

SICOTTE J3H-A-6 Angular Vertical Boring Machine24" x 72" Table size Angular boring machine for chair seat -- (6) Hydraulic self feed spindle having 3 7/8" adjustable stroke and variable speed feed, 1 HP motor, jacob chuck 0 to 1/2" capacity, mounted on 24"long arms with timing belt drive. -- The spindle can be set at coumpônd angle angle with 30 deg front to back and 15 deg right top left. -- (2) Air holddowns. -- 0" - 8" Vertical table feed hydraulically operated that can be used when you drill vetically without angle, , variable feed and table travel adjustable from front of machine, -- 3 HP hydraulic pump motor with reservoir. Complete with: -- Electrical control system with separate motor controls, -- Single or continous stroke, -- Manual and automatic cycle and foot pedal actuation, -- Selector switch to activate each spindle manually . -- This machine is design for chair seat boring or any other application where angular holes are required.

$4,950

SIEMENS - 75 KVA,... 480 - 380Y/220 Volt 3-Phase Dry Type TransformerSpecifications: -- General purpose: Intended for power, heating, and lighting applications. -- Enclosure Rating: NEMA 3R ventilated; for indoor or outdoor use. -- Multi-tap (432-504) Primary 480 V (Delta); Secondary 380/220 Volt Y - 60 HZ ventilated. -- Aluminum winding material. -- NEMA Class ANN. -- Catalog # 3F6Y075FCD16.(2) Available; priced per unit; make offer for both!

SIERRA - RB5000, ...Portable Baler/LoggerNew in 2011 - Less than 500 hoursFeatures and Specifications: -- Faster cycle times equals higher production volume. -- Features an easy-to-load loading box that opens to 16’-5"; x 8’-1"; and short-stroke rams that greatly reduce cycle times. These powerful rams crush each load with 240 tons of force per side, producing:Logging production: 16 - 22 Tons per hourBaling production: 10 - 14 Tons per hour -- The "RB5000" is the perfect machine for any scrap yard that receives appliances, sheet iron, smaller automobiles & automobile shells, clips, and busheling as their main source of material. -- The "RB5000" Portable Baler/Logger compresses logs and bales to shredder and mill specifications. -- Typical log density: 25 to 35 Lbs. per cubic foot. Average overall weight: 1400 lbs. -- Typical bale density: 80 to 90 lbs. per cubic foot. Average overall weight: 850 lbs. -- Any transfer station that receives a high volume of appliances and sheet iron can also greatly reduce freight costs by baling and logging. -- The structural details and proper design protect the key components of the "RB5000". -- The solid self-framed construction of this portable baler/logger includes SIERRA’s: Standard L-box shaped design, 11/16th-inch abrasion-resistant steel Hardox 450 liner plates, and outer honeycomb construction creating a greater box integrity and adding to the "RB5000’s" longevity. -- For added versatility, the Crane is independent of the Baler, has a continuous rotation, and is fully operational while the Baler/Logger is in use, increasing productivity. -- The Crane features 24-2/3 Ft. boom length and 4,400 Lbs capacity while fully extended and includes an orange peel grapple with a rotator that was specifically designed to handle bales and logs. The well-designed cab and agronomical controls were designed for comfort, safety, and long-term use.

Call for Price

SIERRA - 700T: Shear BalerSpecifications: -- Motors: (2) Electric 100 HP. -- Preload Table. -- Precompression. -- Shearing: 14 - 17 Tons per hour. -- Baling: 12 - 14 Tons per hour. -- Logging: 15 - 17 Tons per hour. -- Cylinders: (1) Main Compression ram; (6) folding box rams. -- Cylinder forces: Shear - 700 tons precompression; 115 tons main compression; 160 tons folding box; (6) cylinders @ 80 tons each; 240 tons each side. -- Folding Box Dimensions: 19 Ft. x 8 in. x 7-2/3 ft. Open: 19 Ft.; 8 in. x 32 in. x 24 in. Closed: 34 In. x 22 in.Shear Throat -- Disassembled approx. (3) years ago. -- Running when removed from service.

Call for Price

SIERRA - 700T, ...Shear BalerSpecifications: -- (2) 100 HP Electric Motors -- Preload Table -- Precompression -- Shearing: 14 - 17 Tons per hour -- Baling: 12 - 14 Tons per hour -- Logging: 15 - 17 Tons per hour -- Cylinders: (1) Main Compression ram; (6) folding box rams. -- Cylinder forces: Shear - 700 tons precompression; 115 tons main compression; 160 tons folding box; (6) cylinders @ 80 tons each; 240 tons each side. -- Folding Box Dimensions: 19 ft., 8 in. x 7-2/3 ft. Open: 19 Ft., 8 in. x 32 in. x 24 in. Closed: 34 In. x 22 in.Shear Throat

SIERRA - RB6000, ...Portable Baler/Logger - New in 2020Approx 9,300 HoursThe RB6000’s automatic baling and logging cycles keep you at peak efficiency. Baling: 12 - 16 Tons per hourLogging: 18 - 22 Tons per hourAutomobile Logging: 26 - 32 Tons per hourThe RB6000 baler/logger is a beast on automobiles, appliances, and lightweight sheet iron; producing logs with the density you need to meet max weight. Looking to produce mil-spec bales?The RB6000’s cylinder comes within 18 inches of each other allowing you to densely bale clips and busheling to mill specifications.Average Bale and Log specifications:Bales: Size (40 in. X 24 in. X Variable), Weight (850 lbs.)Logs: Size (40 in. X 24 in. X Variable), Weight (1200 - 1400 lbs.)The portability of the RB6000 baler/logger gives you the versatility you need with the capability of being moved to multiple locations or to different areas within the same location.The hydraulic powered outriggers provide the needed stability to handle the heavy weight of the machine.

SIERRA T556SLK Shear/Baler/LoggerApproximately 3500 hoursThe T556SLK shear/baler/logger was designed with strength, mobility, and time efficiency. It is available diesel or electric and is a true workhorse that doesn’t require a special foundation. After a two-day assembly process, it is ready to work for you. Easily transportable, the SLK series can be taken from yard to yard with ease, and there is no need for an operator as they come fully equipped with the remote-control operation.With 556 tons of cutting force, the T556SLK shear/baler/logger has unmatched versatility and is ideal for scrap processors, C&D facilities, and Demolition contractors.Shear:Foundry scrap, pipe, beams, plate, HMS #1, HMS #2Shearing production: 16-22 tons per hourBale:Clean sheet, wire, lightweight scrap, tin, clipsSize (31"; x 25 x Variable), Weight (900 lbs. average)Baling production: 16-22 tons per hourLog:Appliances, automobiles, sheet metal, tinSize (31"; x 25"; x Variable), Weight (1200 lbs. average)Logging production: 18-22 tons per hourAs with all Sierra machines, the T556SLK is expertly manufactured with an innovative L-Box-shaped design, 11/16th-inch replaceable abrasion-resistant steel Hardox 450 liner plates, and outer honeycomb construction, creating greater box integrity.

SILVER - SJK-65: Construction & Line Boring Machine(4) Vertical Boring Heads; 21-spindle from bottom on 32 mm centers; (1) Horizontal Boring Head; (21) spindles on 32 mm center. -- 3" (75 mm) Max. drilling depth; (3) 4.0 HP - 3,450 RPM motors; pneumatic-hydraulic drill head advance with: Speed control with working speed or (0 - 15) cycles per min.; head height adjustment with: Mechanical digital readout; 51" x 37" working capacity. -- Equipped with: (2) Pneumatic holddown clamps; pneumatic foot pedal control.

SILVER SJK-21 Horizontal & Vertical Boring on 32 mm centers.(21) Spindles in line on one boring head (aluminum alloy single block), drills vertically from top & horizontally from rear. -- Features pneumatic adjustment for horizontal boring.Specifications: -- Max drill dia. is 1.38" (35 mm); Max panel thickness is 2.36" (60 mm); Table size 36" x 19.75" (914 x 502 mm). -- Length of cross fence is 102" (2,600 mm); length of aluminum table fences are 39" (1,000 mm) to the left and 28" (710 mm) to the right with flip stops.Equipped with: -- Depth stop adjustment, (2) holddown air cylinders, and foot pedal operation for clamping/drilling cycle. -- 2 HP - 3,600 RPM TEFC motor with thermal overload protection and low voltage controls.. -- Includes (12) Quick change chucks..

SILVER SJK-19T Line Boring MachineSingle line vertical boring machine with (19) spindles at 32 mm centers driven through a powerful 1.5 HP motor.Equipped with: -- Foot pedal controlled pneumatic boring cycle -- Adjustable boring feed speed -- Adjustable boring depth for fast changeover -- 2 Pneumatic cylinder clamp for solid hold-down to the material. -- 3 Meter long back fence for long line boring with flip stops -- (2) Positioning pins at both end of boring head to set up for longer line boring quickly -- Quick change chuck for fast changeover (19 pcs included)Specifications: -- No. of Spindles....................................................................................... 19 -- Distance between each spindle.............................................................. 32 mm -- Max Boring Depth .................................................................................. 60 mm (2.36") -- Working Table Size................................................................................ 800 x 500 mm (31.5" X 19.68") -- Table Height from Floor......................................................................... 780 mm (30.35") -- Max Boring Depth from Edge................................................................. 155 mm (6") -- Electric .................................................................................................. 220 V / 60 Cy / 3-Ph -- Machine Size (LxWxH) ........................................................................... 920 X 670 X 1490 mm (36.25" x 26.37" X 58.66") -- Net Weight ............................................................................................ 220 kgs. (484 Lbs)

$27,500

SILVER 6023AH Moulder Feed Through 6-Head (B-R-L-T-T-B), working cap. 9-1/16" x 6". Head sequence: -- Bottom 10 HP, top 10 HP, right 10 HP, left 10 HP, top 15 HP, top 15 HP and bottom 15 HP motor. -- Spindle dia. 40 mm with cutterhead speed of 6,000 RPM. -- All spindles with mechanical digital readouts. -- Feed: Variable speed of 18 - 82 FPM, with 5 HP feed drive motor. Powered feed rollers top and bottom. -- Infeed: Straightening table 2 M (6'6"), with side pressure roller and table lubrication pump. Includes:: -- Centralized control panel, -- Sound and safety enclosure.

6 Ft. x 20 Ft., Single-Deck Vibrating Screen;Complete with the following features: --Counterweight type Drive with TEFC Motor. -- Food grade construction throughout. -- Accessible hinged Feed Box. -- Dust Cover. -- Double-crowned Screen Ball Deck with (6) Wire Screens. -- Total screening area of 6’x20’. -- Fines Collection Hopper with Discharge Spout. -- Factory Frame. NOTE: ● This is a single-cut screen for two outputs. ● Never Used.

$29,900

SIMI 5' x 10' HOT PRESS Platen dimension 123" x 63" (3,125 mm x 1,600 mm). -- Max. daylight opening 17" (430 mm). -- (8) Hydraulic upstroke cylinders with diam. 6" (150 mm). -- Electrically heated platens with a maximum heating temperature of 240 F (120° C) -- Loading on all (4) sides of press.Overall dimensions: Length 165" x 81" x 117-1/4"

Call for Price

SMART 60" Pallet Band Dismantler Specifications: -- 60" Bay -- (1) 15 HP Blade Drive Motor. -- Hydraulic powered table lift. -- Adjustable table height to allow the machine to dismantle a range of different heights of wooden shipping pallets. -- New controls

SNX nVISION System2 G2 CONTOUR EDGEBANDER + Optional Dual Telescoping Arms for simultaneous Contour Banding & Trimming: -- Specifications: Curved (Contour) Edgebander to allow 360° edgebanding to contoured (shaped) panels.Edgebanding is applied automatically as part is advanced past the edgebanding workstations via turntable.Reduced learning curve/expertise for operation as operator simply loads part to vacuum turntable, then activates the edgebanding cycle. -- Working Capacity: The nVision Contour Bander can band a minimum material size of 150 mm (6") diameter.Maximum material size 2,400 x 2,400 mm (94" x 94"); Maximum material weight up to 104.5 KG (230 LBS).Material thickness from 10 - 60 mm (0.4" - 2.36"); Banding thickness from 0.5 mm thin tape w/low temp adhesive - 3mm tape. -- Radii Capacity:Minimum Internal (inside) radius 80 mm (3.14"); minimum external (outside) radius 30 mm (1'18") based on 1 mm thick edge tape. ● Edgebanding thickness 1 mm, min = R 30 mm ● Edge thickness 2 mm, min = R 50 mm ● Edge thickness 3 mm, min = R 80 mm ● Panel thickness 10-60 mm with edge thickness 1 mm ● Panel thickness 10-60 mm with edge thickness 2 mm ● Panel thickness 10-45 mm with edge thickness 3 mmIMPORTANT: ALL minimum & maximum radii are affected by tape thickness, quality of adhesive and edgebanding being applied. Radius size dramatically affected by adhesive temperature and quality of edge tape, semi or rigid. -- Equipped with:(1) Thermal-regulated glue pot heated via (2) 800-Watt heating elements with electronic temperature controls; holds up to 1 KG (2.2 LBS) of granules. (2) Pressure rollers to copy the shape of the piece, automatic guillotine for coiled material up to 3 mm (0.11") thickness & 57 mm height (0.125" - 2.25"). -- Features: TRIAX 3-AXIS Laser System (patented) for tighter butt joints & easy length identification with closed parts without the need for additional length measurement.The Laser also detects a tight radius and will automatically slow the speed + resume the set speed when the detected radius has passed.The machine is also equipped with the foot pedal for manual control/intervention. Motorized turntable for automated edgebanding application to large panels.(2) "Heavy Duty" Articulating arms to support the parts during edgebanding and trimming. Arm has a large inter-changeable vacuum pod to secure panels during edging and trimming.NOTE: Panels can be irregular in shape but must conform to the min. tolerances of inner & outer radii and fit within the work area. -- Complete with: ● Top & Bottom Trimming unit ● Centralized control panel with Simple PLC Touchscreen Interface with individual controls for all stations to enable manual feeding of panels if desired ● Banding station ● Edgeband coil stand ● Standard-size vacuum pod for articulated arm ● 80 mm dia. (3") dust extraction outlet ● Foot pedal activation/de-activation control ● Larger feed roller